Reference

Automation equipment: evaluation and selection of efficient production lines

| Filename | Automation equipment-evaluation and selection of efficient production lines.pdf |

| File Size | 1.0MB |

| Revision Date | 2025/04/22 |

Automation equipment: How to Choose the Right Automation Equipment Manufacturer to Creating a High-Efficiency Production Line

In today's increasingly competitive manufacturing environment, implementing automation equipment and automation machinery is no longer optional—it is a crucial strategy for business transformation and upgrading. Whether it's to address labor shortages, improve production consistency, or optimize overall capacity, automation systems play a key role. However, there is no single approach that suits every company when it comes to implementing automation equipment. Choosing the right solution tailored to your production line needs directly impacts your return on investment and production efficiency.

This article explores the key considerations for introducing automation equipment from three main perspectives: identifying needs, selecting the right equipment, and prioritizing customization services.

1. Clarify Needs and Define Your Automation Goals

Before evaluating automation equipment, businesses should address the following critical questions:

-

What is the purpose of automation?

Is it to solve labor shortages, increase capacity, or improve yield rates? -

What are the current production bottlenecks?

Are certain stations time-consuming or prone to rework? These insights help determine automation priorities. -

What are the characteristics and variability of the production process?

If product specifications change frequently, modular and flexible designs should be prioritized in equipment selection.

2. Key Considerations When Selecting Automation Equipment

When choosing automation equipment and automation machinery, evaluate the following aspects:

(1) Does the equipment's functionality match actual production needs?

Over-specified equipment not only wastes budget but may also increase operational complexity. Choose systems that are modular, expandable, and scalable to accommodate future production changes.

(2) Automation level and control system

The degree of automation should align with production pace and output goals. Common types of automation machinery include:

-

Automated assembly machines: Suitable for highly repetitive tasks with steady production cycles.

-

Single-axis or multi-axis dedicated machines: Built for specific processes with high stability and efficiency.

-

Multi-station rotary indexing machines: Enable multiple processes to be performed simultaneously, significantly boosting output density.

Equipped with PLC controllers and human-machine interfaces (HMI), these systems enhance usability and enable easier monitoring and maintenance.

(3) System stability and ease of maintenance

Choose automation machinery with a streamlined structure and a high degree of parts standardization to reduce maintenance costs and minimize downtime. It's also crucial to partner with suppliers offering comprehensive after-sales service and technical support.

3. Prioritize Customization Services

Every production line is unique, and the idea of “one standard machine fits all” is no longer viable. Partnering with a manufacturer that provides customized automation equipment design is essential.

Experienced automation equipment manufacturers can tailor designs based on the customer's actual process requirements—from mechanical design and fixture development to control logic programming. Our goal is to create automation solutions that meet user needs precisely, not force users to adapt to the machines.

4. Value-Added Benefits of Automation

Choosing the right automation equipment and team brings long-term operational advantages:

-

Reduce reliance on manual labor and minimize operational risks

-

Improve yield rates and quality consistency

-

Enable real-time monitoring and data reporting through digital systems

-

Lay the foundation for smart manufacturing and production automation

In addition to specializing in the design and manufacturing of automated pad printing machines and automated screen printing machines, FINECAUSE has been deeply rooted in the printing industry for many years, committed to providing customers with highly efficient and stable printing solutions. However, our expertise is not limited to printing alone — we also have extensive experience in the development and manufacturing of automation equipment and automated machinery across various industries.

Below are examples of automation solutions we developed based on our clients' specific production needs and within their budget:

Case Studies: Customized Automation Equipment Solutions

Case 1: FA-600S2-BS Spray Coating Machine | Automation equipment manufacturing

The client wanted to add automation functionality to their existing spray machine. We designed a dual-axis servo platform to allow programmable spray range control. The system supports adjustable movement speeds, one-way or two-way spraying, and both intermittent and continuous spray modes.

Features include a stainless-steel enclosure for direct water rinsing, a 7.0-inch color touch screen for easy control, and recipe-based parameter settings with multi-formula storage.

Case 2: FA-400F2-KY – Automated Plasma Machine for SD Card Processing

The client required bulk plasma treatment for SD cards. We designed a plasma machine with an XY servo platform, a lifting module, and a blower system to prevent parts from being displaced during treatment.

Users can set start and end positions for the plasma head and enter the number of rows and columns to auto-generate arrays. Operation is intuitive and efficient.

Case 3: FC-01097-AUTO-FE – Fully Automatic Cleaning Machine for Contact Lens Manufacturing

Cleaning is critical in the contact lens manufacturing process. We provided a precision 6-station rotary indexing table with inverter-controlled positioning and pump/filtration systems to ensure clean water quality.

The system includes automated loading/unloading arms, dual RO-filtered water stations, and smart cleaning logic that only activates when materials are detected. It supports 20 custom cleaning recipes for quick formula switching.

Other solutions include the FC-AOI500 Automatic detection machine by CCD, FJP-001 Automatic spray coating machine, XY-arm XY Auto-Array Robot Arm, Fully Automatic Bottle Printing Machine, FC-1636-BRC Fully automatic multi color pad printing machine, Automatic Flat Screen Printing Machines, and Automatic Pad Printing Machine.

In addition to comprehensive automation equipment design, we also provide automation upgrades for existing machines. Contact us for a customized assessment and solution planning.

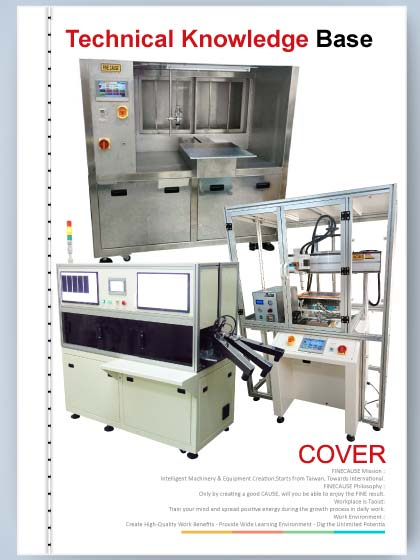

Featured Equipment

Conclusion

Investing in automation equipment is not just about buying a machine—it's about choosing a long-term solution. Only by starting with your real needs and leveraging expert equipment design and integration can you unlock the full value of automation and achieve sustainable competitiveness.

At Fine Cause, we provide end-to-end services covering the planning, design, and manufacturing of automation machinery. With integrated system planning capabilities, we build dedicated assembly machines, single-axis and multi-axis systems, rotary processing machines, and high-efficiency automated screw fastening machines for various industries.

We understand that every customer has unique process conditions and production layouts. That's why Fine Cause offers highly flexible and diversified custom manufacturing services. From concept design to equipment delivery, our professional team helps businesses accelerate automation, improve production efficiency, reduce labor costs, and enhance quality consistency.

Choosing Fine Cause means choosing a trusted partner for your automation upgrade.

If you're seeking a reliable automation equipment manufacturer or planning to implement or upgrade automation systems, feel free to contact our expert team. We're here to develop the best custom automation solution for your production line.

FC-1636-BRC-Multicolor pad printer/Fully automatic multi color pad printing machine

Links

Links