Reference

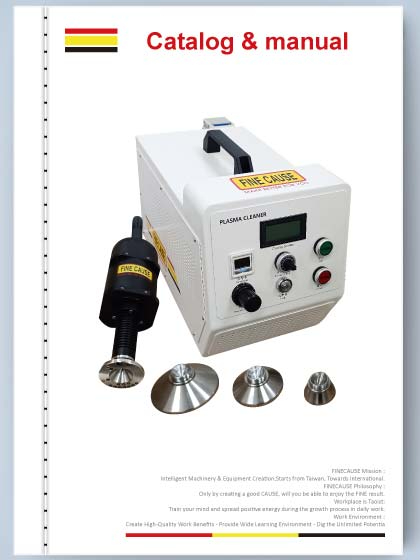

Plasma Surface Treatment Machine (Rotating Gun)-F1Z-1000

| Filename | F1Z-1000-Plasma-Treatment-Machine.pdf |

| File Size | 409.7KB |

| Revision Date | 2024/07/16 |

Plasma Surface Treatment Machine (Rotating Gun)-F1Z-1000

Advantages of Plasma Treatment Machine:

-

High Activation Performance

-

Significantly enhances the wettability of material surfaces, creating active surfaces that facilitate subsequent coating and bonding.

-

-

Enhanced Coating Adhesion

-

Through surface coating treatment, improves surface adhesion, increasing bonding reliability and durability, suitable for industrial coating and bonding processes.

-

-

Excellent Cleaning Effect

-

Effectively removes dust and oil stains, achieving fine cleaning and eliminating static electricity, particularly suitable for applications requiring high cleanliness.

-

-

Improves Printing Quality

-

As a pre-printing surface treatment, it significantly increases ink adhesion, enhancing printing quality.

-

-

Multi-functional Surface Treatment

-

Suitable for various materials, such as polymer plastics, ceramics, glass, PVC, paper, and metals, enhancing surface energy and improving surface tension characteristics to meet different industrial needs.

-

-

Gentle Treatment, Material Protection

-

Uses low-temperature plasma technology to break molecular bonds on the material surface, increasing chemical reaction activity without affecting the material’s base properties, ideal for treating heat-sensitive polymer materials.

-

Wide Range of Applications:

-

Electronics Industry

-

Suitable for LCD screens, casings and buttons, PCB surface cleaning, lens pre-bonding treatment, wire and cable marking pre-treatment.

-

-

Automotive Industry

-

Used for pre-bonding treatment of car lampshades, brake pads, and door sealing strips.

-

-

Mechanical Industry

-

Metal parts cleaning, lens coating pre-treatment, industrial materials bonding and sealing pre-treatment.

-

-

Printing and Packaging Machinery

-

Pre-gluing treatment of edge positions.

-

-

Medical Equipment

-

Pre-bonding treatment of needles and plastic catheters.

-

-

Surface Printing, Hot Stamping, Adhesion, Pre-gluing Treatment

-

Cleaning and activation of various material surfaces, improving adhesion.

Precision-Controlled Three-dimensional Surface Modification

-

Utilizes low-temperature plasma flow treatment technology to achieve three-dimensional object surface modification, providing uniform and stable treatment effects.

-

No warm-up required, ready to use, can be started and stopped at any time.

Superior to Corona Treatment

-

Plasma treatment machines can achieve surface energy levels more than 10 dyn higher than corona treatment machines. For UV or water-based ink printing on PP and BOPP, plasma ion treatment is required.

*Note: Dyne value is the surface energy of a material; the higher the value, the better the material can accept ink adhesion. Water-based ink has the poorest adhesion, so the surface dyne value needs to be high.

.......please download the file if you need the DM content, please click the Download button to download.

Links

Links