Reference

Which Silk Screen Printing Machine Should You Choose? Pneumatic, Servo Motor, or Fully Electric Screen Printer?

| Filename | Which Screen Printing Machine to Choose.pdf |

| File Size | 376.2KB |

| Revision Date | 2025/03/11 |

Screen printer manufacturers teach you how to choose the right screen printing machine.

Select a silk screen printing machine Based on Graphic Size

When choosing a silk screen printing machine, consider the maximum printing area required, as this determines the machine’s stroke length.

Screen Printing is Ideal for Large Graphics

Screen printing is well-suited for larger designs, capable of handling graphics up to 100–200 cm. If large-area printing is needed, screen printing is the better option.

Screen Size Considerations

When using a silk screen printing machine, the screen itself needs to be slightly larger than the design. Extra space is required for the squeegee to move left and right for ink application and coverage. Typically, an additional 10–14 cm of space is left on both sides beyond the printed content.

Types of Screen Printing Equipment

-

Manual screen printing is done using a hand printing table.

-

Screen printing machines are categorized into flat screen printing machines and curved screen printing machines.

-

There are semi-automatic screen printing machines, automatic flat screen printing machines, and automatic curved screen printing machines (also known as fully automatic bottle printing machines).

There are pneumatic flat screen printers, servo motor screen printer, and fully electric servo screen printing machine. So, which screen printing equipment should you choose?

Each type has its own advantages, and through the following analysis, you can make a choice based on your own needs!

The Development History of screen printing equipment

1. Early Development: pneumatic screen printer

Traditional screen printing in the early days commonly used pneumatic flat screen printers. The advantage of this type of machine lies in its low manufacturing cost. Therefore, during an era that emphasized large-scale, high-volume production, many brands adopted this type of screen printer.

Even today, pneumatic flat screen printers are still available on the market. Due to their affordable price, they remain a choice for those with budget constraints or for applications where high precision is not a top priority.

2. Technological Advancement: Application of Variable-Speed Motors and Servo Motors

-

As time progressed and the demand for technological products increased, traditional pneumatic flat screen printers began to be gradually phased out. The ink scraping drive systems started to use variable-speed motors. In further development, especially in the printing of glass panels, light guide plates, and other precision objects, more and more machines started to use servo motors for the ink scraping action.

-

The advantage of servo motors lies in their digital control and stable operation. Especially when printing on transparent materials, servo motors can provide even, stable, and controllable effects, improving print quality.

3. The Popularization of Servo Motors

Ten years ago, Fine Cause introduced affordable servo ink scraping screen printing machines. By mass-producing components to reduce costs, servo ink scraping technology is no longer exclusive to high-tech applications, gradually spreading to general industrial and consumer goods screen printing. This technology’s popularization has made quality control in screen printing easier, significantly improving the print quality of these products.

4. The Rise of Fully Electric Screen Printing Machines

-

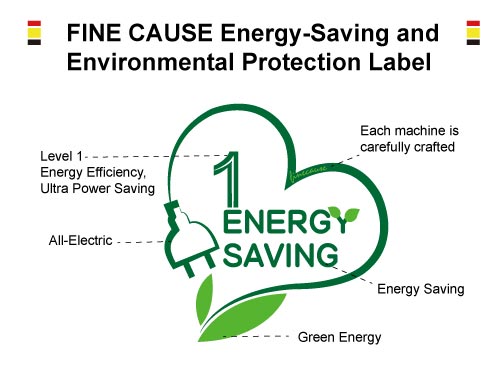

In recent years, with the widespread adoption of industrial digital control technology, fully electric screen printing machines have gradually gained the favor of the market. Compared with traditional pneumatic flat screen printers, electric systems operate more stably and delicately, aligning with the current energy-saving and carbon-reduction trends.

-

Compared to cylinder systems that require air compressors, air tanks, and refrigerant dryers for complex air pressure conversions, electric systems can avoid the energy losses associated with multiple energy conversions. In addition, the pressure loss of pneumatic systems is much greater than that of voltage loss, making fully electric screen printing machines more efficient in energy use.

5. Future Development Directions

To meet broader market demands and align with energy-saving trends, Fine Cause has launched the Electric Desktop Screen Printing Machine and the High-End Fully Electric Flat Screen Printer, covering the screen printer product line. We continue to refine our technology with professionalism and a pragmatic approach.

FA-300 400TGN-Electric Desktop Screen Printing Machine

The full-electric screen printing machine that integrates energy savings, time efficiency, and ink conservation. Certified with the FINECAUSE energy-saving label, saving approximately 80% of electricity compared to traditional pneumatic screen printing machines. The parameter settings are digitalized, and 30 sets of formulas can be stored. The signal indication panel displays the status of the input and output signals, making operation clear at a glance.

If you have high requirements for printing precision, the high-end fully electric servo pad printer can meet your needs and is also a screen printing machine that enhances production efficiency.

FA-400TZN-Electric Flat Screen Printer

The electric screen printer is not used air pressure. No need the pneumatic cylinder and no need to connect to air pressure source. super power-efficient! fully digitized settings and completely unaffected by air pressure. The screen printer can be operated as long as it is plugged in. Adopt stepper motor to let the squeegee stand up and down linearly. The setting is precise without effort. The operation is fast, stable, and quiet.

Smart memory with one-click formula switching. Fast, stable, and quiet operation.

Energy Consumption Comparison Table of Three Screen Printing Machines

| Model | Machine Drive Type | Control Ability of Printing Quality | Energy Consumption | Unit Price |

|---|---|---|---|---|

| TCN Pneumatic Flat Screen Printer | Relies solely on pneumatic power; electricity is only used for control | Slightly lower | High | Low |

| TSN Servo Screen Printer | Servo used for critical squeegee movement, others still use pneumatic | Medium | Medium | Medium |

| TZN All-Electric Screen Printer | Every movement is driven by servo and stepper motors | High | Low | High |

Annual Electricity Savings of the Three Screen Printing Machines

| Model | Air Compressor Power (W) | Freeze Dryer Power (W) | Total Power Consumption (W) | Hourly Power Consumption (kWh) | Daily Power Consumption (kWh) | Monthly Power Consumption (kWh) | Annual Power Consumption (kWh) | Energy Ratio | Saved Electricity |

|---|---|---|---|---|---|---|---|---|---|

| FA-400TCN | 2238 | 600 | 2838 | 2.838 | 22.704 | 499.488 | 5993.856 | 100% | 0% |

| FA-400TSN | 1692 | 400 | 2092 | 2.092 | 16.736 | 368.192 | 4418.304 | 73.71% | 26.29% |

| FA-400TZN | X | X | 575 | 0.575 | 4.6 | 101.2 | 1214.4 | 20.26% | 79.74% |

Power Consumption Calculation

FA-400TCN calculated with a 3-horsepower air compressor: 3 * 746W = 2238W

FA-400TSN calculated with a 2-horsepower air compressor: 2 * 746W = 1492W + 200W (half for the motor)

Assuming 8 hours of work per day, approximately 22 working days per month, and around 264 working days per year (excluding weekends and holidays).

The power consumption of the three models within the same time frame is as follows.

1 kWh = 1,000 watt-hours (1,000 Wh) = 1 kilowatt-hour (1 kWh)

Annual power consumption of pneumatic flat screen printer = 5993.856 kWh

Annual power consumption of servo screen printer = 4418.304 kWh

Annual power consumption of fully electric servo screen printing machine = 1214.4 kWh

If comparing the fully electric servo screen printing machine with the pneumatic flat screen printer, using these values in the formula:

Percentage saved = 1214.4 ÷ 5993.856 = 0.2026

Percentage saved = (1 - 0.2026) × 100 = 79.74%

Therefore, the FA-400TZN fully electric servo screen printing machine saves approximately 79.74% of the electricity compared to the FA-400TCN pneumatic flat screen printer.

Meanwhile, the FA-400TSN servo screen printer also saves about 26.29% of the electricity compared to the FA-400TCN pneumatic flat screen printer.

The fully electric screen printing machine does not require pneumatic systems, does not use cylinders, and can be operated just by plugging it in without an air supply. Not relying on pneumatic systems eliminates the potential impact of air pressure fluctuations on print quality, providing more stable printing performance. A general semi-automatic screen printing machine requires a pneumatic system, which is the biggest difference. No need for air pressure means more energy savings!

Fully electric screen printing machines provide higher print quality. Thanks to their digital control and servo systems, they can achieve more accurate position control and more stable printing pressure. The downward pressure of the squeegee is controlled by a stepper motor, which allows fine adjustments to the pressure distance, making it ideal for high-end screen printing. This is something that general semi-automatic screen printing machines do not offer.

Which Screen Printing Equipment Should You Choose?

If budget and space considerations are a priority, this desktop screen printing machine is also available in the 400 model. The desktop pneumatic version is more compact, features simple buttons, offers easy operation, and consumes relatively less power!

FA-300 400THN-Desktop Screen Printing Machine/Screen Printer

The screen remains stationary during printing, eliminating the need for lifting. This slows down ink evaporation, significantly reducing ink consumption. The reciprocating speed of sliding table can be adjusted in order to increase printing productivity. Ink scraping process is moved by pneumatic cylinder which is stable and effortless. The dimension of the printer is small, which is able to place on the desktop directly and easy to transport. It is the first choice for novice with economical price. Made in Taiwan. Great value for money!

If you need a balance between standard functionality and budget, the FA-400TSN servo screen printer is a great choice. The TSN standard mass-production series delivers excellent precision and printing quality!

Produced directly from the factory with the 【most competitive pricing】, high-performance servo motor. Max printing area:300/400/500 mm respectively. The printable height is up to 200 mm. semi auto screen printing machine using precise servo motor movement stable movement stable, printing more accurate. screen printing easy to move up and down, stable and quiet. Extended Warranty to 3 Years for Screen Printer.

Fully electric servo screen printing machines may be more expensive initially, but you won't need to spend extra on an air compressor. You can operate it simply by plugging it in. Moreover, in the long run, the savings on electricity costs will be substantial! If you have large printing volumes and demand precision and quality, the FA-400TZN fully electric servo screen printer is the best choice!

No matter which screen printing equipment you choose, we provide the highest quality products and services to ensure your production process is more efficient and stable. You can click on the product names above to visit the product pages for a complete introduction. If you would like to learn more about product features or apply for a trial, please feel free to contact us.

Discover more about our Standard Screen Printing Machine series and Fully Automatic Screen Printers.

Links

Links