Reference

Curved screen printer adjustment tutorial-【Part 1】

| Filename | Curved screen printer adjustment tutorial-Part 1.pdf |

| File Size | 234.4KB |

| Revision Date | 2023/03/16 |

Curved screen printer adjustment tutorial-Part 1

FA-400 RSN semi-auto curved screen printer tutorial video Part 1

-

Turn on the screen printing machine

-

Turn the power and air pressure on and push default start point botton. The machine will search for default start point automatically.

-

-

Fix the substrate need to be printed

-

Fix the jig or adjust the position of pulley rollers and put the subtrate on it. Take a close look at the substrate and adjust its initial level. To have more precise level adjustment after the screen stencil is installed.

-

-

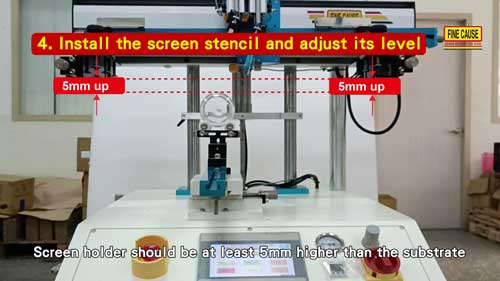

Adjust screen holder of the screen printer

-

Push screen position down botton to make the holder in the printing position. Screen holder should be at least 5mm higher than the substrate.

-

-

Install the screen stencil on the screen printing machine and adjust its level

-

Push squeegee stand up botton to make the squeegee stand in upper position. Install the screen stencil and fix it by tightening the screws.

-

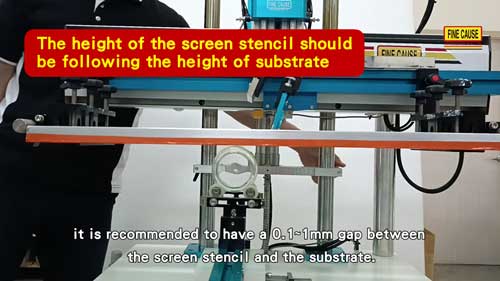

Stand by the printer and lower your body, eyes on the same height with the substrate and the screen stencil.

-

-

Adjust the level of substrate and the height of screen stencil.

-

The level should be in accordance with the screen stencil. Adjust substrate's level until it's parallel with the screen stencil.

-

The height of the screen stencil should be following the height of substrate. Screen stencil cannot be lower than the highest point of the substrate.

-

※It is recommended to have a 0.1~1mm gap between the screen stencil and the substrate.

Please download the file if you need the complete content, please click the Download button to download.

To be continued Part 2

1. Adjust the squeegee

2. Adjust the ink blade

Links

Links