Reference

How to Select Pad-Print and Screen-Print

| Filename | How to Select Pad-Print and Screen-Print-EN.pdf |

| File Size | 446.7KB |

| Revision Date | 2024/08/29 |

How to Select Pad-Print and Screen-Print

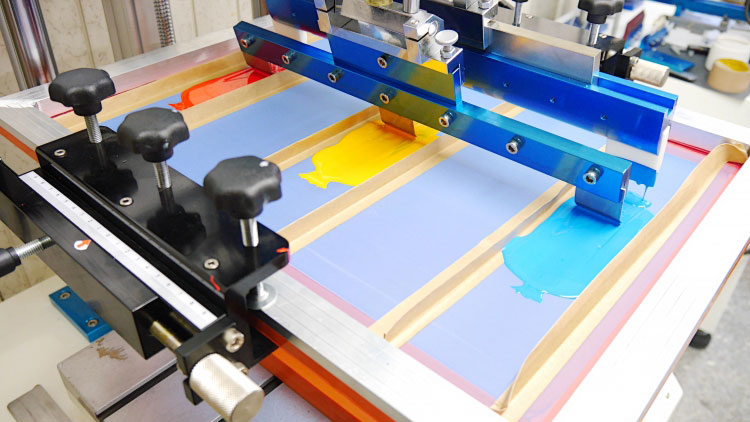

Printing Method Selection - Choosing Pad Printing or Screen Printing?

When selecting a printing process, pad printing and screen printing are two common techniques, each with its unique advantages suitable for different printing needs. The choice of method primarily depends on the following factors: the material of the object being printed, its shape, the size and thickness of the printed graphics, and other specific requirements.

■ Material of the Object Being Printed

Both pad printing and screen printing can be applied to a wide range of materials, including plastic, metal, ceramic, glass, rubber, paper, and fabric. This means that when choosing a process, material is generally not a limiting factor.

■ Shape of the Object Being Printed

Pad printing, with its flexible silicone pad, can print on objects of various shapes, including flat, concave, convex, curved, and irregular surfaces. Therefore, pad printing is especially suitable for objects with complex shapes or irregular surface textures. In contrast, screen printing is more suitable for flat and simple curved surfaces, such as cylindrical or conical shapes.

■ Size of the Printed Graphics

In general, pad printing is better suited for fine, small graphic printing because it can accurately reproduce details. On the other hand, screen printing excels in larger graphic printing and can even handle graphic content up to 100 to 200 cm, making it a better choice for large-area printing.

■ Thickness of the Printed Graphics

In terms of printing thickness, pad printing is usually thinner, with the thickness after printing typically below 0.01 mm. Conversely, screen printing offers greater control over thickness, allowing adjustments through the thickness of the screen mesh and the hardness of the squeegee. Therefore, if there are specific requirements for the thickness of the printed layer, screen printing might be more suitable.

■ Other Characteristics

Pad printing uses fast-drying inks, making it especially suitable for multi-color printing. Screen printing offers more variety in ink selection, including not only volatile inks but also UV inks, strong adhesives, chemicals, and even thermal paste. Additionally, screen printing plates are more economical to produce compared to pad printing plates.

[Click here for recommended pad printing inks]

[Click here for recommended screen printing inks]

■ Summary

When choosing between pad printing and screen printing, it's essential to evaluate based on the material, shape, size, and thickness of the printed graphics, as well as specific printing needs. If you need to print on irregular surfaces or require fine graphic printing, pad printing is the ideal choice; for large-area printing or tasks requiring thickness control, screen printing has a distinct advantage.

For beginners or low-volume printing, pad printing outsourcing is recommended.

For standard mass production, the ANC series of pad printing machines is recommended.

For beginners or low-volume printing, screen printing outsourcing is recommended.

For standard mass production, the TSN series of screen printing machines is recommended.

Comparison Table of Pad Printing and Screen Printing Characteristics

| Project | Pad Printing-Characteristics | Pcreen Printing-Characteristics |

|---|---|---|

| Material of Printed Object | Plastic, Metal, Ceramic, Glass, Rubber, Paper, Cloth and etc. | Plastic, Metal, Ceramic, Glass, Rubber, Paper, Cloth and etc. |

| Shape of Printed Object | Plane, Concave, Convex, Curved, Irregular Surface,Texture Surface | Plane, Curved Shape (Cylinder, Cone) |

| Printed Pattern |

|

|

| Pattern Thickness | Thinner. The thickness of the printed pattern is less than 0.01mm | Thicker. The thickness can be controlled by screen’s thickness and hardness of the squeegee. |

| Other Characteristics |

|

|

please download the file if you need the complete content, please click the Download button to download.

Links

Links