Reference

Pad printer machine scraping ink is not clean, problem resolve

| Filename | Pad printer machine scraping ink is not clean-problem resolve.pdf |

| File Size | 95.2KB |

| Revision Date | 2024/08/13 |

Pad printer machine scraping ink is not clean, problem resolve

How should you address the issue when the ink scraping in an ink cup pad printing machine is not clean?

The possible causes of the unclean scraping of ink are organized as follows

The structure of the ink cup is

A: Ink cup main components are

(1)Ink cup plastic body :

Long time immersion in corrosive solvents may cause the body to expand deformat , which will adversely affect the shape of the blade ring and result in dirty ink scraping .

(2)Packing O-ring :

Long time immersion in corrosive ink, will cause the Packing deterioration, , deformation, , reduce the service life. When finish work it is recommended to clean the ink cup everyday .

(3)Blade ring :

If the blade is hit , which may cause the blade to damaged , you can use the back of the nail to touch it in a circle to check whether it is missing.

Note: Using improper inks , or additives , some inks will contain powder particles that are too large and too hard, which will affect the life of the blade ring .

In normal use, blade ring`s life can scrape ink at least 2 million times .

Note : Do not use empty ink cup or a small amount of ink to be scratch , it will cause serious damage to the blade ring.

B: Cliché

-

(1)The flatness of the Cliché must be within 0.03mm.

-

(2)When the Cliché is scraped , the same scraping position must be maintained . If Cliché is scrapes 10000 times on machine A then scrapes ink 10000 times on the machine B , it is easy to leak ink due to different scraping tracks .

-

(3)Generally the Cliché with hardness above 62 degrees can scrape ink 200,000 times continuously , but Cliché with insufficient hardness will quickyly cause ink leakage .

-

(4)Too many times of repeated grinding and remaking of the Cliché, surface decreases , and the times of scratch resistance will also be reduced .

-

(5)The pattern of single time ink staining must be consistent with the etching pattern of the Cliché .The pattern that do not allow the rubber pad to be inked every time , the ink is scraped are easily squeezed by the scraper to push ink to the outer ring , causing ink leakage .

C: Ink cup cover

There have strong magent installed at the bottom of the ink cup cover , and the high temperature will cause the magnetic field to disappear or decrease , which will affect the ink cup cover is not fit enough and leak ink .

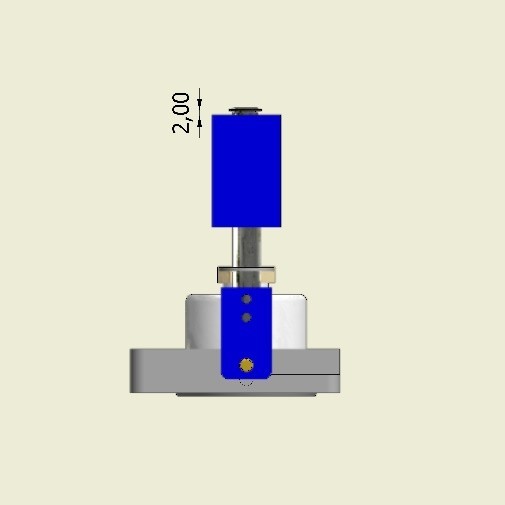

D: Ink Cup holder

(1) Ink cup holder should be horizontallock, unless external forces are not easy to damage .

(2) At least 2mm when the holder bracket is pressed under the ink cup cover .

E: Ink

Please use the ink and additives specially for pad printing . The size and hardness of the color powder particles will affect the life of the blade ring , Unsuitable inks or additives will cause serious damage to the blade ring and ink leakage at first scratch.

F: Level of steel plate seat

This condition is usually inspected before leaving the factory. By scraping ink back and forth , and the upper edge of the frame pillar`s protruding dimensions to understand the level of the steel plate seat .

Please click this link for our pad printing machines...

please download the file if you need the complete content, please click the Download button to download.

Links

Links