Reference

Silk screen knowledge

| Filename | Silk Screen Printing - Details to Note When Making Screens.pdf |

| File Size | 139.3KB |

| Revision Date | 2024/08/14 |

Silk Screen Knowledge

Silk Screen Printing - Details to Note When Making Screens

Screen Size

Hand Printing: When using handprint,the screen can printed by adding about 5cm to the upper,lower,left,and right.

Mechanical Printing: Add at least 10 cm on the left and right sides for ink scraping, and 5 cm on the top and bottom (excluding the frame).

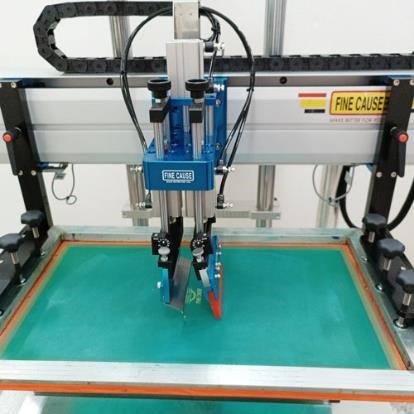

Finecause's New Generation Servo Screen Printer: It is recommended to leave 14 cm on the left and right sides.

Screen Tension (Unit: Newton)

Nylon Mesh: The tension of nylon mesh is generally between 0~3 Newtons. Lower tension provides more elasticity and softness, making it suitable for printing materials with varying elevations and for special frame screens.

Tedoron Mesh: Tedron generally use 12~14Newtons.When the tension is greater,the distance between the screen and the material can be closer,conversely it is far,usually 2~4mm from the grid.

Screen Film Thickness

Directly affects the thickness of the printed ink layer. Generally, a film thickness of 10 μm is used. Thicker films produce thicker coatings.

The hardness of the squeegee and the angle of ink application also affect the print thickness, but not as much as the film thickness.

Silk Color

Yellow Silk: When exposed, ultraviolet (UV) light is used, which has a mixed reflection of cyan and red hues. Since black lacks the yellow hue, when UV light is added with the yellow hue during exposure, it forms black. Therefore, the yellow silk screen surface is less sensitive to light or lightly exposed, resulting in high image clarity without vignetting.

White Silk: When light passes through the transparent part of the film and reaches the emulsion layer, reflections, refractions, and slow diffusion occur on the surface of the white silk screen in the middle or bottom of the coating layer. This causes "back exposure," which can lead to ghosting and affect tone reproduction.

Screen Mesh Count

Fewer Meshes: Suitable for printing cloth, paper, ceramic plastic embryos, and other materials that absorb water. Fewer meshes mean larger holes, faster ink flow, and require fewer meshes for thicker ink coatings.

More Meshes: Generally used for printing on plastics, metals, and text with 300 meshes. More meshes mean smaller holes, slower ink flow, and require thinner ink coatings.

Mesh Material

Nylon: More elastic and softer, suitable for printing materials with varying elevations. The elasticity of the nylon mesh prevents the screen from being easily scratched by the squeegee pressure.

Tedoron: Less elastic and harder, suitable for printing flat surfaces or where precise printing positions are required.

[Click here for Screen Stencil For Screen Printing.]

please download the file if you need the complete content, please click the Download button to download.

Links

Links