Reference

The relationship between screen printing and printing

| Filename | The relationship between screen printing and printing.pdf |

| File Size | 474.3KB |

| Revision Date | 2024/08/22 |

The relationship between screen printing and printing

Screen printing method - The printed pattern is composed by thousands of the small holes (mesh) on screen plate. Pouring the ink on the screen plate and place the printed object underneath. The ink will go through the mesh and print the pattern on the object. It is aslo called “Silk-Screen Printing”because the screen material is silk.

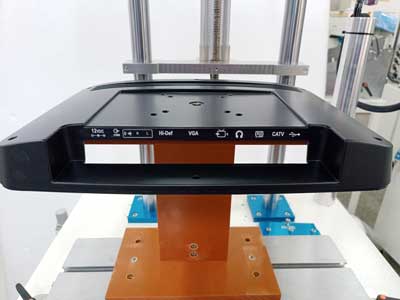

Screen printing is a versatile printing. It can be used to print on a variety of materials such as clothes, ceramics, tea sets, electrical appliances, large billboards, plastic, metal and high-tech related products. It has become a indispensable technology nowadays.

-

When printing on very thin and lightweight materials, it is usually necessary to use a printing platform with a vacuum function, especially when the printing area is large. This is because the adhesive nature of the ink can cause the lightweight material to stick to it. Additionally, the vacuum function is sometimes used for easier positioning.

-

Typically, Epoxy Putty is commonly used to create fixtures due to its quick and convenient production process.

-

ther methods include using bakelite material with a milling machine or CNC processing, or using resin casting.

-

Regardless of the method used, maintaining the level of the printing surface is very important, although the requirements are not as stringent as in screen printing.

-

If the printed pattern is too close to the edge of the material, it is best to add a spacer (the height of the spacershould be lower than the material). Without adding a spacer, there is a risk of skipping during printing. Insummary, the area surrounding the printed pattern needs to be supported during the squeegee process. Thesqueegee direction requires about 3-5 cm of support, and the left and right edges of the squeegee require about2cmofsupport.

-

For curved surface printing, the material needs to have the same center and radius for either a circle or an arc; it doesn’t necessarily need to be cylindrical. Conical shapes can also be printed, though they are more challenging.

■Screen Stencil For Screen Printing

-

Mesh Density – Commonly used from 50 mesh to 480 mesh. To print absorbent material such as cloth, paper and ceramic, it is better to use less mesh screen. The less the mesh, the faster the ink is effused. If the ink is more concentrated, you need less mesh screen.

-

Screen Material –The material of the mesh is divided into nylon (more stretchable and elastic) and Tetoron (less elastic).

-

If the printing material has a slight width, it is more suitable to use nylon mesh (the squeegee will not be deformed due to the pressure of the screen). Usually for general flat printing or those that require accurate printing position, Teodoron screen is mostly used.

-

Tension of the Screen – Dralon screen or the screen with high tension, the screen can be closed to the printed object. Normally, the distance is about 2~4mm.

-

Screen Membrane – If the membrane is thick, the printed pattern is thicker. Squeegee softness and the scraping angle also affect the thickness of the printed pattern but the inpact is not as big.

-

For the size of the screen, when using handprinting, the screen needs to be approximately 5cm above andbelow the artwork. If mechanical printing is used, at least 10cm should be added to the left and right squeegeedirections,and5cmshouldbeaddedtothe top andbottom.

There are 5 types of the squeege:

Four-corner squeegee, Bevel Angle, Arrow Shape, U-Shape, Profile TRIPLE-LAYER

-

Four-corner squeegee – It is more commonly used for general flat printing. Due to its shape, the squeegee force is stronger than other shapes. Because of this relationship, it is suitable for fine line patterns such as fine characters and dots. But because of this, the thickness of the ink printed by it is thinner than that of other squeegees (the 80-degree four-corner squeegee has some adverse effects on the life of the screen), or it is used when the printing material has deeper textures.The harder four-corner squeegee can produce better adhesion with the printing material, so it is less likely to cause ink spillage due to poor adhesion. It can also be used for curved surface printing with good results.

-

Bevel Angle Squeegee –It is more commonly used when the printing material is slightly uneven. Due to itsshape, the squeegee force is smaller than other shapes. Because of this relationship, it is suitable for thickcharacters and large-area patterns. However, the thickness of the ink printed by it is thicker than that of othersqueegees, or when it is used for curved surface printing and the printing material is not very round, the bevelshapewillplayitsrole. Uniquefeatures.

-

Arrow Shape Squeegee – Normally used on curved printed object. However, if the roundness is not good, do notusethis kind ofsqueegee.

■Printing ink

Ink – If distinguishing by drying methods, they can be divided into 3 kinds: Solvent evaporation type, UV Drying type, and water-based inks.

Solvent Evaporation Ink– The drying speed depends on ignition point of the solvent. The higher the ignition point, the slower the evaporation of the solvent. For the faster evaporation speed, it is better to use on pad-print. When printing, the ink has to be half way dry to be able to deinking. The faster evaporation speed is not suitable for screen printing. The slower the screen printing ink dries, the better.

UV Drying Ink – The drying of the ink is depending on the UV light. Therefore, the feature is that the screen will not be stuffed.

Using the UV light can make the ink solidified instantly. And the degree of the hardness is a lot stronger than the traditional inks. so in It is often used in automated printing. However, the unit price of UV ink is relatively high.

Water-Based Ink – It is evaporated and dried naturally. You can speed it up by using the oven.

There are many different materials of the printed objects; Each object has its own adherence condition; therefore, there are many different brands of the ink and each brand has many different series in order to meet the printing requirements.

Fine Cause Offered Inks:

MARABU (Germany), RUCO (Germany), SEICO (Japan), OPS (Japan)

1. MARABUMARABU Moderate evaporating rate. Suitable for both pad and screen printing SR Series:

Suitable for ABS, PC, Acrylic (Adding hardener is optional)

PU Series: Suitable for PU material like golf balls (Hardener is a must)

PY Series: Suitable for Metal, Coating, IC, Memory Card (Hardener is a must)

GL Series: Suitable for Glass material (Hardener is a must)

2.Germany RUCO (has obtained exclusive agency rights):

Germany RUCO T01 has a moderate evaporation speed and is suitable for screen printing.

-

T110GK series: Suitable for glass, varnished surfaces, metals, thermosetting plastics, polyamide (PA), polycarbonate (PC), pre-treated polyethylene (PE) and polypropylene (PP).

-

T45 series: suitable for ABS, PC, acrylic.

-

T200 series: Suitable for metal and baking paint.

-

T01 Series: Suitable for glass, varnished surfaces, metals, thermosetting plastics, polyamide (PA), polycarbonate (PC),pre-treatedpolyethylene(PE)andpolypropylene(PP).

3.SEIKO (Japan):Moderate evaporating rate. Suitable for both pad and screen printing

- EPOXY1300 Series: Used on metal, coating and glass. Need high tempture baking at 170 degree/30minutes to adhere the ink on object.

-

EPOXY1000 Series: Used on metal, coating and glass. Need high tempture baking at 120 degree/30minutes to adhere the ink on object. (Hardener is a must)

-

VICSeries:UsedonABS,PC,Acrylic(Hardenerisoptional)

4. OPS (Japan) : Moderate evaporating rate. Suitable for both pad and screen printing

OPS Series : Suitable for PP material (Such as Syringe). Not ALL PP material is workable. Best to test it first.

※ Find Cause WK: Moderate evaporating rate.

Suitable for both pad and screen printing. Suitable for ABS, PC, Acrylic

-

Extra Slow Evaporating Solvent: Suitable for screen-print to prevent the stuffed-up.

-

Slow Evaporating Solvent: Normally used on screen-print to dilute the ink. Add the solvent at about 5%

-

Standard Solvent: Normally used on pad-print to dilute the ink.

-

Fast Evaporating Solvent: Normally used on pad-print to dilute the ink.

-

Extra Fast Evaporating Solvent: Normally used on pad-print to dilute the ink. Accelerating the evaporation will enhance the deinking effect.

-

Ink Cleaner: Used to clean up the printing defects. When wiping the products, it’s not damaging the surface of ABS, PC or Acrylic.

-

Cleanup Solution:Used to clean screen/steel plate

■AdditivesAdditives(auxiliaries):

Ruco EB anti-stringing agent: suitable for pad printing and screen printing. Improve the fluidity of ink and eliminate bubbles in ink, thereby improving the effect of fine printing.

Marabu ST1 Extender Base : Suitable for both pad and screen printing. It is used to reduce the viscosity of the ink. It is recommended to add it at about 10%.

Condensing Agent: Used on screen printing to prevent ink diffusion. Adding 10~20% the condensing agent into ink can slow down the evaporating of the ink. It can reduce ink viscosity to prevent the ink flow in order to increase resolution of the printed pattern. Normally, it’s used for small design, line or the printed object with rough surface. It is also suitable for pad-print. The only concern is that it may reduce the concentration of the ink color and loss of the surface smoothness if it is used in excess.

VM1 Flow Agent: Suitable for both pad and screen printing. The flow agent can increase the flow of the ink. It can also eliminate the problem of the ink causing bubbles or pinpoints on the printing surface to make the surface smooth and pretty. Adding the flow agent no more than 5% to prevent the printed pattern diffusin.

■Adjustment steps of screen printing machine :

-

Close the Pneumatic Valve. Normally, there is a sliding switch at the entrance of the air compression valve called Pneumatic Valve.

-

Lock the jig on the platform at the correct place and direction.

-

Placed the printed object and have it fixed on the jig.

-

Make the screen plate fixed on the screen folder.

-

Adjust the height of the screen folder (1.5~4mm higher than the printed object) and lock it with the screw. If it is urved object printing, remember to adjust the tooth bar underneath the T-shape bar.

-

Adjust the printing position. For this, we need to check the position of the screen plate and the printed object (Look from the top) and then lock the screen folder tight.

-

Adjust the height and horizontal level of the ink-scraping knife. Make the knife just a bit higher than the screen and parallel to it.

-

Adjust the height, angle and horizontal level of the squeegee and make it touched the printed object and parallel to it. (The straighter the angle of the squeegee is, the better the exaustion. However, it is no good for uneven surface ).

-

Adjust the distance of the right-hand side sensor (S3) and make the ink-scraping knife position over the printed pattern.

-

Adjust the distance of the left-hand side sensor (S4) and make the squeegee position over the printed pattern for about 10mm. This is to prevent bad printing caused by buffer pads on 2 sides.

-

Turn on the Machine power and open the Pneumatic Valve.

-

Pourtheink,presssemi-autoswitchandstartprinting.

■Printing Problems :

Q1: Unable to print out the pattern or the pattern printed is incomplete.

A:

-

If the squeegee pressing distance is not enough when printing (when it is not covered with ink), the remaining ink will be found on the screen.

-

The ink is too thick-Usually the ink is too thick and only part of the pattern cannot be printed, and the printed pattern is prone to stringiness due to too thick viscosity.

-

Bad squeegee levelness-If the levelness of the squeegee is not good enough, you will find that one side of the pattern can not be printed out.

-

Ink dried too fast-The signs that the ink dries too quickly are similar to the second sign that the ink is too thick. However, if you check the fluidity of the ink and find that it has considerable fluidity but cannot print a pattern, it is most likely that the ink dries too quickly. The finer the pattern, the more likely it is that the ink dries too quickly. The more likely it is that the ink will not print due to the ink being too thick or drying too quickly.

-

Failure to print immediately after pouring the ink causes screen clogging.

Q2: The printed pattern shows overflow ink

A:

-

Ink is too thin

-

Wrinkles on the surface of the printed object (Using harder squeegee, fasten printing speed, using high-density ink or adding condensing agent can solve this problem)

-

Scraping speed istoo slow

Q3: The printed pattern shows double shadow

A:

-

Printed object is too close to the screen plate

-

Printed object is moving when printing

-

If it is curve-screen-print, make sure to adjust the tooth bar under the T-shape metal base so that printed object is in the center with squeegee contact line.

-

Check to see if the squeegee bounces when pressing and lifting it. (There must be more than 20mm of support before and after printing the pattern).

If you have any unresolved printing issues, please click the form at this link and our professional team will be happy to resolve it for you!

please download the file if you need the complete content, please click the Download button to download.

Links

Links