Reference

How to Select the Silicone Pad Printing Pads?

| Filename | How to Select the Silicone Pad Printing Pads.pdf |

| File Size | 471.8KB |

| Revision Date | 2024/08/15 |

How to Select the Silicone Pad Printing Pads?

Silicone Pad Printing Pads Hardness Guide (Click here to request a free copy)

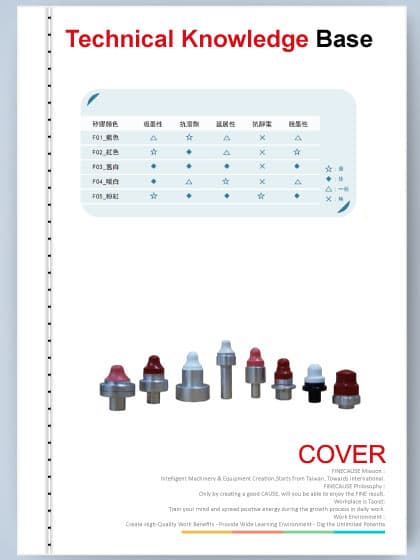

| ★Excellent ●Good △Average X None | |||||

|---|---|---|---|---|---|

| Silicone color | Ink absorbency | Solvent resistance | Ink deposit | Anti-static | Extensibility |

| Blue | △ | ★ | △ | X | △ |

| Red | ★ | ● | ★ | X | △ |

| White | ★ | △ | ● | X | ★ |

| Pink | ★ | △ | △ | ★ | ● |

| Grey | ★ | △ | ★ | X | ● |

Silicone Colors

Generally, we use different colors to distinguish pads’materials.

-

Blue: Excellent solvent resistance and stronger toughness extend the lifespan of the pads, making it suitable for high-volume printing

-

Red: Excellent ink absorption and deposit, suitable for use on prints with poor ventilation and textured surface substrates.

-

White: Excellent flexibility, suitable for use with soft pads, less prone to damage when covering irregular substrates.

-

Pink: It possesses anti-static properties and excellent ink absorption, allowing for the complete presentation of fine fonts.

-

Grey: Excellent ink absorption and deposit, minimal feathering on fine fonts, and excellent saturation.

Shapes & Sizes of the Pad Printing Pads

-

Normally, we select the pads basing on the sizes of the printed pattern.

-

If there are many fine lines, we use sharper and harder pads.

-

Use bigger/softer/flater pads for bigger printed patterns.

-

If there is combination of the patterns, use combinative pads.

-

When pressing the pad to a certain level, the pressing angle is not good for exhaustion. Therefore, do not choose too small pads when basing on printed size.

-

When using harder pad, the pressing speed must exceed ink-floating speed. Otherwise, the underflow-ink might occur.

-

When the ink contains too many bubbles, a harder pad can sometimes discharge the air out of the ink.

-

When the printed area is curved, the deformation occurs when you press the pad too fast.

Hardness of the Pad Printing Pads

-

Some silcone are soft and suitable fpr soft pads.

-

However, some silcone are only suitable for hard pads. If making it into soft pads, it will reduce the life of the pads.

-

Normally, the sharper/harder the pads are, the better exhaustion they are.

-

Therefore, we use sharper/harder pads for thinner lines and patterns.

-

Hard pads are with better exhaustion but it is also easier to cause underflow-ink.

-

For bigger area printing, use softer pads to avoid uneven shades.

-

The harder the pads are, the greater that the pads can hold when printing.

Ink Absorption for Pad Printing Pads

-

Better anti-solvent pads, the ink absorption is worse.

-

Old pads’ ink absorption is better than new pads.

-

Printing in advance to test the concentrated dilutions of the ink. If the evaporation is ok but the pad still can’t absorb the inks, use the cloth to clean up the pad.

-

While wiping the pad surface can improve ink absorption, it may also reduce deinking performance.

-

Avoid pausing too long before applying ink or leaving the machine idle with the plate exposed, as this can cause incomplete ink transfer.

Deinking of the Pad Printing Pads

-

The longer the pads are used, the deinking is worse because of the solvent

-

corrosion to the pads and friction between pads and printed objects.

-

The faster the ink evaporating speed, the better the deinking is.

-

Before pressing the pad onto the object, allow it to rest for 0.3 to 1.5 seconds to let the ink partially dry, which helps with deinking.

-

Using a blower for assistance, especially in colder temperatures, can further improve results.

-

The deinking effect is the best when the pad ink is at semi-dry state.

-

The deinking process can be done successfully more than 10,000 times per day.

Life of the Pad Printing Pads

Normally, a pad can be used 10K – 50K times.

Factors affecting the pad lives:

A. Squeezing Variant

B. Solvent Corrosion

C. Oxidation

|

This product is suitable for softer/flater pad printing pad.

|

|

This product is suitable for sharper/harder pad printing pad.

|

Silicone Pad Printing Pads Hardness Guide (Click here to request a free copy)

please download the file if you need the complete content, please click the Download button to download.

Links

Links