Reference

How to Choose Between a Plasma Treatment Machine and a Corona Treatment Machine?

| Filename | PlasmaTreatmentMachine-or-CoronaTreatmentMachine.pdf |

| File Size | 405.5KB |

| Revision Date | 2025/06/13 |

Surface Treatment Before Printing: A Safe and Fast New Choice.

How to Choose Between a Plasma Treatment Machine and a Corona Treatment Machine?

When considering whether to choose a corona treatment machine or a plasma treatment machine, understanding their different characteristics and pros and cons is crucial for selecting the equipment that best meets your needs.

Advantages of Plasma Treatment Machines:

-

Wide Material Applicability: Suitable for various materials, including plastics, metals, glass, ceramics, paper, etc.

-

Suitable for Curved and Irregular Surfaces: Ideal for treating materials with curved and irregular shapes, such as bottles, containers, plastic tubes, rubber tires, etc.

-

Efficient Surface Treatment: Capable of deep treatment, providing better results, especially suitable for high-precision and high-cleanliness applications.

-

Low-Temperature Treatment: Suitable for heat-sensitive materials, without damaging the base material.

-

Versatility: Provides multiple surface treatment functions, including cleaning, activation, and coating, meeting various industrial needs.

-

Safety: Can safely treat metal materials without causing conductivity or combustion.

-

Higher Treatment Efficiency: Plasma treatment machines can achieve dyne levels over 10 higher than corona treatment machines, necessary for UV or water-based ink printing on PP and BOPP.

-

Dyne Level: Indicates the surface energy of the material. The higher the dyne level, the better the ink adhesion. Water-based inks have the poorest adhesion, requiring high dyne levels on the material surface.

Advantages of Corona Treatment Machines:

-

Suitable for Various Materials: Ideal for plastic films, sheets, aluminum foil, metallized films (such as PP, PE, PET, OPP, PS, ABS, etc.), paper, and fibers.

-

Curved Surface Corona Treatment: Especially suitable for treating curved and irregularly shaped materials, such as bottles, containers, plastic tubes, rubber tires, etc.

-

Lower Equipment Cost: Corona treatment machines have lower purchase and operating costs.

-

Simple Operation: Easier to operate and maintain, without the need for highly specialized technicians.

-

Safety: Corona treatment machines use low-temperature high-energy treatment, which is safe and non-combustible.

-

Efficient Surface Activation: Significantly enhances the surface energy of materials, making inks and coatings adhere more easily.

-

No Air Supply Needed: Does not require an air compressor or external air supply.

Selection Recommendations:

-

Plasma Treatment Machine: If you handle a variety of materials, including metals and glass, and require high-precision, high-cleanliness surface treatment, the F1Z-1000 Plasma Surface Treatment Machine (Rotating Gun) is your best choice.

-

Curved Surface Corona Treatment Machine: If you need to treat not only flat materials but also curved and irregularly shaped materials, such as bottles and containers, while controlling costs and simplifying operations, the FC-FGX-D Curved Surface Corona Treatment Machine will better meet your needs.

-

Sheet Corona Treatment Machine: If you mainly handle plastic films or sheet packaging materials and want easy and simple treatment, the FC-P40 Sheet Corona Treatment Machine is more suitable for you.

No matter which equipment you choose, we provide the highest quality products and services to ensure your production process is more efficient and stable. You can click on the product names above to view the complete introduction on their respective product pages. For further details or to apply for a trial, feel free to contact us anytime.

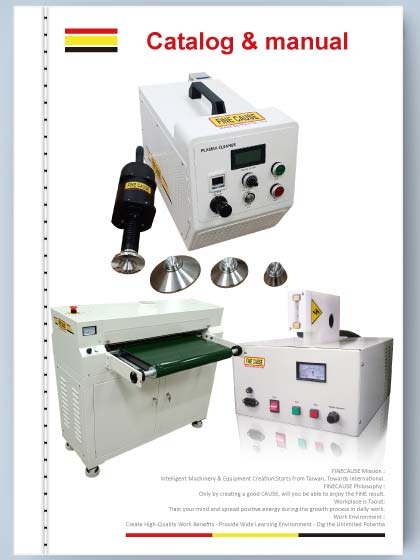

▲Above: F1Z-1000-Plasma Surface Treatment Machine (Rotating Gun)

Below: FC-FGX-D-Curved Surface Corona Treatment Machine

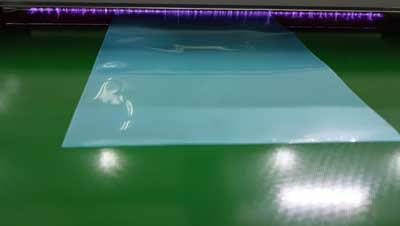

▲Above: FC-P40-Sheet Corona Treater

| Which is Better: Plasma Treatment Machine or Corona Treatment Machine? | ||

|---|---|---|

| Differences | General Plasma Surface Treatment Machine | General Corona Treatment Machine / Curved Surface Corona Machine |

| Principle | Uses high-frequency high-voltage electric field to generate plasma in gas, where high-energy particles bombard the material surface. | Uses high-voltage electric field to create corona discharge on the material surface, where high-energy electrons bombard the material surface. |

| Air Source Connection | Requires air compressor / air connection | No air connection required |

| Material Suitability | Various materials (plastic, metal, glass, ceramic, paper, etc.) | Most effective for plastic and film materials |

| Surface Treatment Depth | Deep treatment, better effect | Used for surface treatment, quick processing |

| Heat Impact | Low temperature treatment, suitable for heat-sensitive materials, does not damage the substrate | Generates higher heat during the process, some heat-sensitive materials are not suitable |

| Multifunctionality | Provides multiple surface treatment functions such as cleaning, activation, and coating | Mainly used for activation and surface energy enhancement |

| Precision Control | Precisely controls processing power, suitable for high-precision requirements | Simple control, suitable for less precise requirements |

| Treating Three-dimensional Objects | Can treat three-dimensional objects, curved and irregular shapes, bottles, containers, wider application range | Sheet corona treater: Mainly suitable for flat and film materials Curved surface corona treater: Can treat three-dimensional objects, curved and irregular shapes, bottles, containers, wider application range |

| Equipment Cost | Relatively higher cost | Relatively lower cost |

| Operation Complexity | FINECAUSE corona treatment machines are easy to operate. | FINECAUSE curved surface corona treatment machines / sheet corona treatment machines are easy to operate. |

| Suitable Industries | Suitable for curved surfaces, bottles, containers, electronic products, medical equipment, high-performance coatings, etc. | Suitable for surface treatment of bottles, containers, plastic films, packaging materials, etc. |

| Printing Assistance | Increases surface energy of various printing materials, improves ink adhesion, enhances ink absorption, and improves printing quality | Increases surface energy of materials, enhances ink adhesion |

| Cleaning Effect | Excellent cleaning effect, removes dust and oil, eliminates static electricity. Enhances adhesion between different materials, increases product strength and durability | Basic cleaning effect, removes static electricity and enhances surface energy |

Rotary Plasma Surface Treatment Machine

(Flat and Curved Shapes Shared - Servo)

▲ FMPT-XYZ XYZ 3-axis gantry motion platform of rotating gun plasma treatment machine

...For the complete color image file, please click the Download button.

Links

Links