Reference

Screen Printing Knowledge-Part 4 Screen Printer

| Filename | ScreenPrintingKnowledge-Part-4.pdf |

| File Size | 282.6KB |

| Revision Date | 2023/02/07 |

Screen Printing Knowledge-Part 4 Screen Printer

0:00 Squeegee speed and snap-off distance of screen printing machine

-

Ink scraping speed -the contact time between the ink and the printed object.

-

-

The ink scraping speed depends on the ink. The ink scraping speed should be slower if the ink is thicker or has higher viscosity.

-

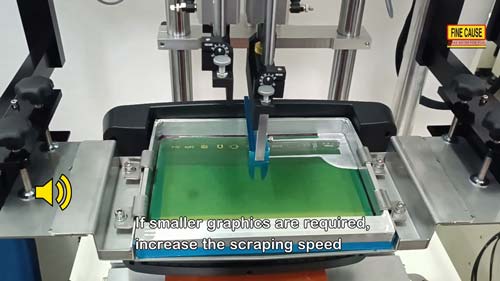

0:33 Smaller graphics /Speed up scraping speed.

- If smaller graphics are required, increase the scraping speed to shorten the contact time between the ink and the printed object.

0:52 Snap-off distance in screen printing

-

Why 【a distance between the screen stencil and the printed object】 is needed in screen printing?(also known as snap-off distance)

-

Because the ink on the screen and the substrate should【 be contacted in a split second】.

-

If the contact time is too long, the ink will be likely spreading around, which results the printed lines become thicker.

-

One more reason to have a snap-off distance is that the ink is easy to stick to the screen if the printed graphics are not released from the screen as soon as possible, the image will be uneven or to have ink picks.

-

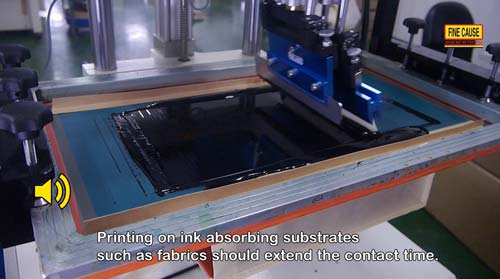

1:32 Printing on ink absorbing substrates

- Printing on ink absorbing substrates such as fabrics should extend the contact time. So, U-shaped squeegee will often be used. Because the contact surface is larger and less pressure is taken, which makes a thicker ink layer.

2:00 Does curved screen printing need a snap-off distance?

-

The printed object will rotate during printing process. The rotation is just like a snap-off distance.

-

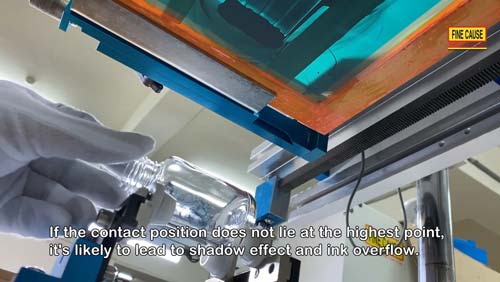

The squeegee’s contact position should be at the highest point of the printed object.

-

-

If the contact position does not lie at the highest point, it’s likely to lead to shadow effect and ink overflow.

🔥Complete collection of screen printing knowledge and screen printing technology

Part 1- Screen Stencil Cleaning

Part 2- Screen printing machine Squeegee

Part 4- Screen Printer/ Screen Printing Machine

Links

Links