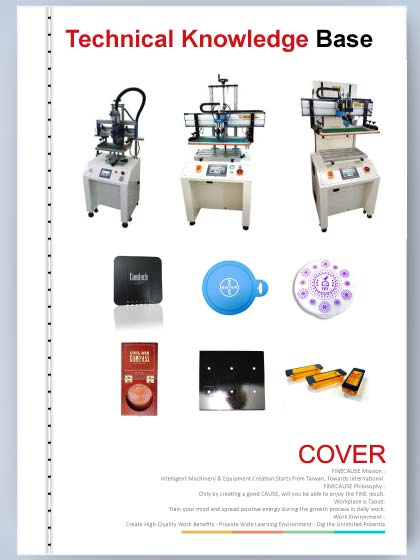

Products

Electric Flat Screen Printer

Electric Flat Screen Printer

Product Info

Flagship Precision Screen Printer – Ultimate Performance and Flawless Printing

🔥 Advanced technology, ultimate precision, intelligent screen printing equipment, ensuring high efficiency and stable production.

🔥 Premium screen printer, delivering exceptional print quality.

✅ Energy-saving screen printer—no air compressor needed, ultra power-efficient!

✅ High-resolution precision screen printing, ensuring every detail is perfectly presented!

✅ Precision screen printing solutions tailored for high-end manufacturing!

Differences Between Electric Screen Printers and Conventional Semi-Automatic and Manual Screen Printing Machines

-

Electric screen printers, unlike conventional semi-automatic or manual screen printers, operate without the need for air pressure. They completely eliminate the use of pneumatic cylinders and air supply. Instead, they can be used simply by plugging them in. This independence from pneumatic systems eradicates the potential impact of air pressure fluctuations on print quality, ensuring a more stable printing performance. On the other hand, conventional semi-automatic screen printers require an air pressure system, representing the most significant distinction.

-

Automation Level: Electric screen printers possess various levels of automation. Equipped with servo systems, digital controls, and automatic adjustment functions, they make the printing process more automated and easier to control. In contrast, certain functions of conventional semi-automatic screen printers might still necessitate manual operation. Print quality could be influenced by the operator's skill.

-

Print Quality: Electric screen printers are capable of delivering higher print quality. Thanks to their digital control and servo systems, they can achieve more precise position control and more stable printing pressure. The ink scraping process utilizes a stepper motor, allowing fine adjustments of the scraping distance, particularly suitable for advanced screen printing. This contributes to achieving clearer and more consistent printing results, a feature absent in typical semi-automatic screen printers.

-

User-Friendly Operation: Electric screen printers generally feature more user-friendly interfaces. The screen lifting and lowering process employs servo motors, allowing fine adjustments of the screen distance from the panel. This enhances the scientific nature of the production process and provides a more intuitive operation method. In contrast, operating a conventional semi-automatic screen printer might require more manual adjustments, making the process more cumbersome.

-

Adjustments and Settings: Electric screen printers may incorporate more automatic adjustment and setting features.

-

Production Efficiency: Electric screen printers typically achieve higher production efficiency. Digital control reduces operational time and often allows for faster printing speeds. The production efficiency of conventional semi-automatic screen printers might be limited by the operator's speed and skill level.

FA-400TZN Electric Flat Screen Printer (Electric Screen Printing Machine)

-

Electric screen printing machine: fully digitized settings and completely unaffected by air pressure.

-

Servo up and down linearly-fast/slow

-

The screen stencil lifting adopts servo motor, allowing precise adjustment of the snap-off distance, making the production process more systematic.

-

Printing action and screen stencil lifting (dual axis)

-

The dual axis can be adjusted manually for left and right printing action/screen stencil lifting speed. The larger the value, the faster the speed. The fastest speed of left and right printing action can reach 999mm/1second.

-

Servo linear lift can be set at a specific position to reduce the lowering speed/screen stencil peel-off speed.

-

There will no issue of squeegee height deviation, which will occur in traditional manual lifting.

-

-

The screen stencil peel-off is actuated by servo motor. The operation is fast, stable, and quiet.

-

Ink scraping adopts servo motor with linear guideway and ball screw rods.

-

The squeegee stand adopts stepper motor to up and down linearly.

-

The squeegee downward pressure is controlled by stepper motor, enabling fine adjustment of the downward distance. This setup is specifically designed for advanced screen printing applications.

-

The squeegee stand up and down in a straight line makes the cleaning of screen stencil easier.

-

Use HMI to adjust the lifting position of the squeegee stand that the setting is precise and effortless.

-

-

7" 65536 colors TFT touch screen. Built-in 5 languages, Traditional Chinese, English, Indonesian, Vietnamese, and Thai.

-

With I/O (input/output), each sensor location is shown in whole area of the machine.

-

With abnormal alarm display, it is convenient for production line personnel to quickly eliminate abnormalities.

-

The usage count of squeegee or screen stencil can be set. When the set value is reached, the device will stop and notice automatically.

-

-

Adopt PLC that the functions is easy to add or modify.

-

Multiple sets of formula can be stored and the parameters can be set.

-

-

Magnetic squeegee clip (Patent No. M390871)

-

The squeegee position can be slided easily and is simple to adjust the position, assemble, and disassemble.

-

-

Production history function: built-in smart bar chart that the productivity, operation time, production speed, etc in the past 30 days can be shown.

-

With WIFI function, if to connect with FineCause smart factory APP, no matter where you are, you can view the machine productivity report anytime and anywhere.

Which screen printing machine to choose? Click here to see the full analysis....

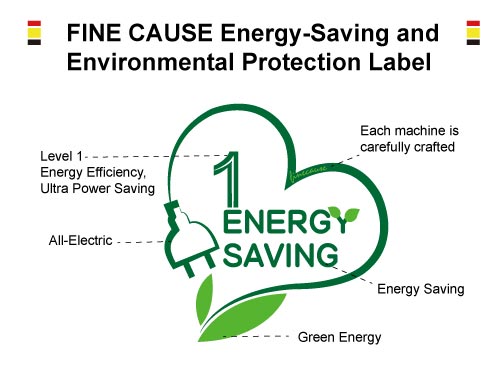

This fully electric screen printing machine not only excels in performance but also boasts the FINECAUSE energy-saving and eco-friendly certification, helping to reduce carbon footprint and achieve substantial energy savings. By choosing our screen printing solution, you are not just investing in your business but also in a greener and more sustainable future. Moreover, with our machine requiring no large pneumatic systems, you can say goodbye to significant investments in air compressor equipment.

At FINECAUSE, we are committed to innovation, energy efficiency, and environmental responsibility. Join us on a journey of precision, energy-saving, and intelligent technology, all wrapped in exceptional quality and design aesthetics. Experience the difference of the FA-400TZN screen printing machine—a perfect blend of performance, sustainability, and professional excellence.

Specifications

| Model/Specification | FA-400TZN |

|---|---|

| Printing Color | 1 |

| Productivity/Hour | 600~1800 |

| Machine Size (cm) | L:70 W:87 H:173 cm |

| Power Consumption (a) | 10A |

| Voltage (V) | Single Phase 220V |

| Platform Size (mm) | 320*500 |

| Max. Printing Area (mm) | 320*300 |

| Allowable Object Height (mm) | 200 |

| Left and Right Stroke (mm) | 400 |

| Screen Stencil Peel Off Height (mm) | 0~400 |

| Max. Screen Stencil Size (cm) | 50*72 |

| Screen Stencil Front and Back Fine Tune Distance (mm) |

±25 |

| Platform Left and Right Fine Tune Distance (mm) |

±8 |

| Platform Left and Right Tilt Angle/ | 10°/50 |

| Lifting Distance of Independent Scraper Set (mm) |

|

| Machine Weight | 250 kg |

Videos

-

Screen Printing Machine/Screen Printer Production Data APP

Screen Printing Machine/Screen Printer Production Data APP

-

Electric Flat Screen Printer (Electric Screen Printing Machine)-FA-400TZN

Electric Flat Screen Printer (Electric Screen Printing Machine)-FA-400TZN

-

Screen Printing Knowledge-Part 4 Screen Printer

Screen Printing Knowledge-Part 4 Screen Printer

-

Screen Printing Knowledge-Part 3 Screen Printing Ink

Screen Printing Knowledge-Part 3 Screen Printing Ink

-

Screen Printing Knowledge-Part-2 Squeegee

Screen Printing Knowledge-Part-2 Squeegee

-

Screen Printing Knowledge-Part-1 Screen Stencil

Screen Printing Knowledge-Part-1 Screen Stencil

Downloads

-

Which Silk Screen Printing Machine Should You Choose? Pneumatic, Servo Motor, or Fully Electric Screen Printer?

Which Silk Screen Printing Machine Should You Choose? Pneumatic, Servo Motor, or Fully Electric Screen Printer?

Which Silk Screen Printing Machine Should You Choose? Pneumatic, Servo Motor, or Fully Electric Screen Printer?

-

FINECAUSE 2020 Smart Servo Motor Screen Printer

FINECAUSE 2020 Smart Servo Motor Screen Printer

FINECAUSE 2020 Smart Servo Motor Screen Printer

-

Smart Pad Printer and Screen Printer APP Connection Setting Operation Manual

Smart Pad Printer and Screen Printer APP Connection Setting Operation Manual

Smart Pad Printer and Screen Printer APP Connection Setting Operation Manual

-

Screen Printing Knowledge-Part 4 Screen Printer

Screen Printing Knowledge-Part 4 Screen Printer

Screen Printing Knowledge-Part 4 Screen Printer

-

Screen Printing Knowledge-Part 3 Screen Printing Ink

Screen Printing Knowledge-Part 3 Screen Printing Ink

Screen Printing Knowledge-Part 3 Screen Printing Ink

-

Part-2 Screen printing machine Squeegee-Screen Printing Knowledge

Part-2 Screen printing machine Squeegee-Screen Printing Knowledge

Part-2 Screen printing machine Squeegee-Screen Printing Knowledge

RFQ form

Thank you for your query, Our specialist will contact you soon.

Links

Links