Products

Automated Machinery Equipment - Double-Color PVC Card Printing Machine - Rotary Table Pad Printer

Automated Machinery Equipment - Double-Color PVC Card Printing Machine - Rotary Table Pad Printer

Product Info

FC-212DRC|Double-Color PVC Card Printing Machine

Automated Machinery Equipment × Rotary Double-Color Pad Printer × AOI Smart Inspection System

The FC-212DRC is a high-efficiency automated pad printer specially designed for PVC card printing. It features a 12-station rotary table and a double-color printing system, integrating auto feeding, AOI inspection and sorting, hot air drying, and a collection conveyor. It is ideal for various PVC card production lines. Successfully adopted by many domestic manufacturers, this model offers high automation, stable operation, and significantly boosts both productivity and quality.

■ Features of This Automated Machinery Equipment

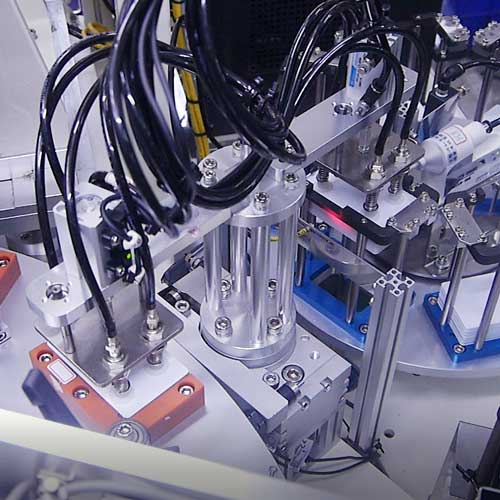

12-Station Rotary Table Platform

Equipped with an indexing positioning mechanism, supporting continuous printing processes with stable and high-precision performance.

Automatic Feeding Module (600-Piece Capacity)

Built-in six-slot storage, combined with an automatic lifting and top-feeding mechanism, improves feeding efficiency. Static electricity blowing function stabilizes feeding quality.

Dual Robotic Arms for Simultaneous Pick-and-Place

Two arms operate in a rotary motion for simultaneous pick-up and placement, achieving high-speed and high-efficiency material handling while minimizing wait time.

Two Standard Pad Printing Machines

Equipped with two pad printer heads, supporting double-color printing operations — ideal for multi-colored logos, graphics, or text.

Z-Axis Adjustment Mechanism

Allows fine vertical adjustments based on workpiece height to ensure optimal printing position.

Hot Air Drying System

Integrates a hot air drying module to effectively shorten ink drying time and speed up the overall printing process.

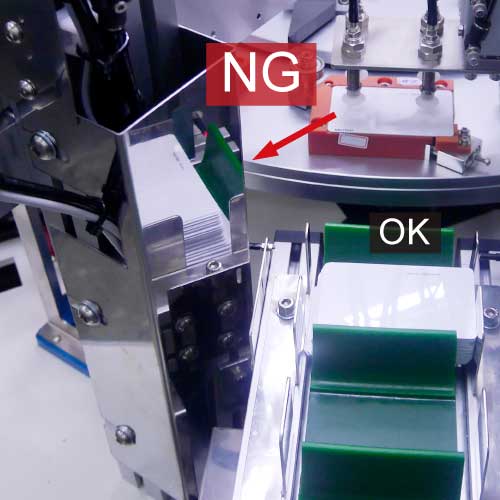

AOI Smart Inspection and NG Collection Mechanism

Built-in visual inspection system automatically identifies and separates defective (NG) products, guiding them to a collection zone to avoid mixing with good products.

Collection Conveyor Design (8 Stations)

Each station can hold up to 50 cards. After automatic classification, cards are sequentially collected, facilitating subsequent packaging or inspection.

Robust and Durable Structural Design

The entire machine is constructed from stainless steel, with partial steel channel components finished with baking paint. The door panels are made of transparent acrylic for durability and operational safety.

▲ Equipped with six-slot storage and an automatic lifting feeding mechanism (600PCS), integrated with a top-feeding mechanism (including static electricity blowing function).

▲ Dual robotic arms operate with a rotary motion to achieve simultaneous pick-and-place, speeding up feeding efficiency.

▲ Integrated hot air drying system.

▲ Equipped with two standard pad printing machines.

▲ Collection conveyor - each station can hold 50PCS, for a total of 8 stations.

▲ Sorting arm - PVC cards identified by AOI are linearly placed either into the NG collection mechanism or onto the collection conveyor.

■ Applicable Industries and Applications

-

Banking / Credit Card Manufacturing Industry

-

Company ID Card / Membership Card Printing

-

Public Transportation Stored Value Cards / Access Control Cards

-

Various PVC Gift Cards / Ticket Card Mass Production

-

Other Customized Card Production Lines

■ Customization Services and Support

We offer comprehensive customized printing equipment design services, including jig adjustments, automatic feeding path designs, pad printing structure enhancements, machine appearance customization, and visual inspection system integration.

Ideal for factories or medium to large-scale manufacturers seeking automation upgrades. Please contact our technical team for further consultation.

FC-212DRC — The perfect combination of automated machinery equipment and intelligent printing.

Contact us today for more technical information and quotations!

▼ The printer is made of stainless steel with some painted channel steel. The door is made of clear acrylic.

▲ Custom pad printer for PVC cards is shipped to domestic customer.

Specifications

| Model | FC-212DRC-SAG |

|---|---|

| Printing Color | 2 |

| Suggested Max. Printing Area (mm) | Ø130 mm |

| Cliché Size in Use (mm) | L:200 W:90 H:10 mm |

| Capacity/Hour | 900~1200 Pcs |

| Machine Size (cm) | L:175 W:150 H:173 cm |

| Weight (kg) | 750 kg |

Videos

-

Fully automatic PVC card printer-FC-212DRC

Fully automatic PVC card printer-FC-212DRC

-

Fine Cause Prints Your Life

Fine Cause Prints Your Life

-

Pad printing machine/Pad printer Production Data APP

Pad printing machine/Pad printer Production Data APP

-

Pad printing machine Fully Upgraded - Price remains unchanged

Pad printing machine Fully Upgraded - Price remains unchanged

-

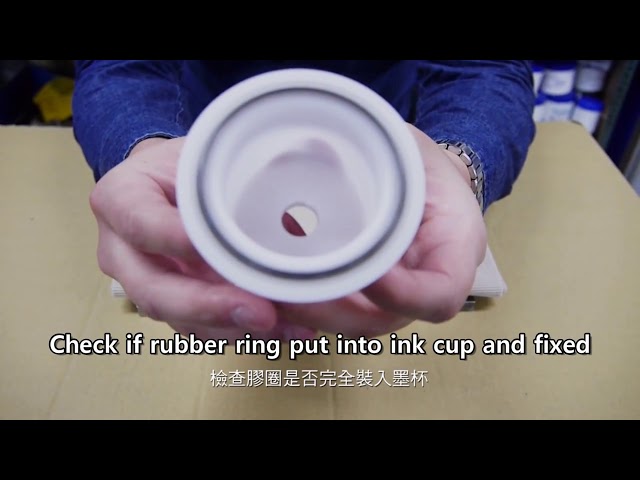

Pad printer Clean Ink Cup tutorial

Pad printer Clean Ink Cup tutorial

-

Instructions - Ink Cup Installation

Instructions - Ink Cup Installation

-

Instructions -Pad printer machine Knife Ring Tutorial

Instructions -Pad printer machine Knife Ring Tutorial

Downloads

-

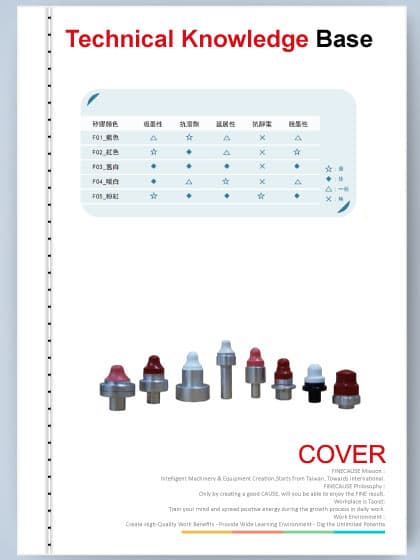

Pad Printers Comprehensive upgrade ~ the price remains unchanged

Pad Printers Comprehensive upgrade ~ the price remains unchanged

Pad Printers Comprehensive upgrade ~ the price remains unchanged

-

German RUCO ink series

German RUCO ink series

German RUCO ink series

-

How to Select the Silicone Pad Printing Pads?

How to Select the Silicone Pad Printing Pads?

How to Select the Silicone Pad Printing Pads?

-

Pad printing technology

Pad printing technology

Pad printing technology

-

Pad printer machine scraping ink is not clean, problem resolve

Pad printer machine scraping ink is not clean, problem resolve

Pad printer machine scraping ink is not clean, problem resolve

-

How to Select Pad-Print and Screen-Print

How to Select Pad-Print and Screen-Print

How to Select Pad-Print and Screen-Print

RFQ form

Thank you for your query, Our specialist will contact you soon.

Links

Links