Products

Insole Printing / Insole Pad Printer

Insole Printing / Insole Pad Printer

Product Info

Insole Printing / Insole Pad Printing Machine

Pad printing replace heat transfers makes mass production of insoles faster. There is no need to prepare a thermal sublimation printer and other consumables like heat transfers. A pad printer does not have the high temperature of heat transfers machine, which will not have the issue of easy scald due to careless operation. The pad printing machine is simple to operate and safe to use. We provide many custom solution for any type of insole, which are well recognized by many sports brands!

| Comparison of Insole Printing Method | |||

|---|---|---|---|

| Printer | Insole Pad Printer | Screen Printer | Heat Transfers |

| Image |  |

|

|

| Equipments & Supplies to be Prepared | ★ Pad printing machine | ★ Screen printer | ★ Sublimation printer |

| ★ Pad printing cliche | ★ Screen stencil | ★ Heat press | |

| ★ Heat transfer paper/film | |||

| Printing Speed | Fast | Middle | Middle |

| Drying Speed | Fast | Slightly slow | Fair |

| Operational Safety | Good | Good | Danger of high temperature and high pressure |

| Summarize | The printing speed is quite fast. There is no need of drying treatment after printing by pad printer; the ink can be dried immediately. Suitable for mass production since the average cost is low. With bright color rendering. | The printing speed is faster than heat transfers; but printing speed and drying speed are not able to be as fast as a pad printer. | The process is time-consuming, which is not suitable for mass production. It is necessary to prepare thermal sublimation printer and other consumbles. Need to pay attention to high temperature of heat transfers, or it will be easy scald due to careless operation. |

■ Suggested insole pad printer: FC-392CRC-MD4 automatic insole printing machine/pad printer

This pad printing machine uses 2 ink cups to print single color on left and right insoles. Equipped with servo lengthened automatic up and down objects storage mechanism. After placing ready-to-print insoles, the insoles will be lifted and clamped to feed and discharge automatically. The printing process is fast, accurate, and convenient! The pressure-regulating ink doctoring mechanism effectively prolongs cliche and ink cup service life. ... click here for full introduction/printing video.

..............................................................................................

■ Suggested insole pad printer: same series but manual objects feeding FC-392CRC-MD insole pad printer/printing machine

▲ Manually feed and place the objects; automatically print and clamp out the objects. The only difference from FC-392CRC-MD4 is that there is no servo lengthened automatic up and down objects storage mechanism and automatic feeding positioning jig mechanism. With automatic discharging gripping mechanism. Pad printer adopts 10" 65536 colors TFT touch screen and built-in 3 languages, traditional Chinese, English, Indonesian. Programmable Logic Controller (PLC) control is easy to add functions. ... click here for full introduction/printing video.

..............................................................................................

■ Suggested standard pad printer: FC-192ANC semi automatic ink cup pad printing machine

This standard pad printer is equipped with 2 ink cups. The ink cups diameter is 90mm. With insole jigs, left and right insoles are able to be printed in single color. Although it is manual feeding and discharging, the printing speed is able to be adjusted by yourself. The printing process is fast and accurate as well! The pad printing machine adopts pressure-regulating ink doctoring system (patent M311585), which can easily adjust the ink scraping pressure of the ink cup. The time can be set through the HMI. Have printing parameter setting and multiple sets of formula storage. The standard model is economical and ideal for novice. ... reference model FC-191ANC semi automatic ink cup pad printing machine; click here for full introduction.

Both standard printer or custom printer, FineCause can provide professional planning and suggestion according to your needs. Welcome to fill in inquiry form for consultation!

Videos

-

FC-392CRC-MD Two-Color Ink Cup Pad Printer w/Index Table

FC-392CRC-MD Two-Color Ink Cup Pad Printer w/Index Table

-

Pad Printing Machine by Temp-control

Pad Printing Machine by Temp-control

-

Ink Cup pad printing machine/Pad Printer Operation and Upgrade

Ink Cup pad printing machine/Pad Printer Operation and Upgrade

-

Pad printing machine/Pad printer Production Data APP

Pad printing machine/Pad printer Production Data APP

-

Pad printing machine Fully Upgraded - Price remains unchanged

Pad printing machine Fully Upgraded - Price remains unchanged

Downloads

-

Pad Printers Comprehensive upgrade ~ the price remains unchanged

Pad Printers Comprehensive upgrade ~ the price remains unchanged

Pad Printers Comprehensive upgrade ~ the price remains unchanged

-

The Relationship Between Pad Printing Plate Etching Depth and Printing

The Relationship Between Pad Printing Plate Etching Depth and Printing

The Relationship Between Pad Printing Plate Etching Depth and Printing

-

SKD11 Material and Heat Treatment

SKD11 Material and Heat Treatment

SKD11 Material and Heat Treatment

-

Pad printing technology

Pad printing technology

Pad printing technology

-

Pad printer machine scraping ink is not clean, problem resolve

Pad printer machine scraping ink is not clean, problem resolve

Pad printer machine scraping ink is not clean, problem resolve

-

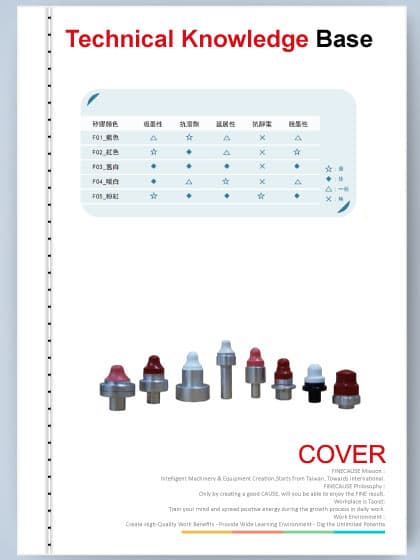

How to Select the Silicone Pad Printing Pads?

How to Select the Silicone Pad Printing Pads?

How to Select the Silicone Pad Printing Pads?

RFQ form

Thank you for your query, Our specialist will contact you soon.

Links

Links