Reference

How to Choose the Right Pad Printing Machine?

| Filename | How to Choose the Right Pad Printing Machine.pdf |

| File Size | 397.6KB |

| Revision Date | 2025/03/12 |

All-electric or pneumatic pad printer—which is better?

How to Choose the Right Pad Printing Machine?

When purchasing a pad printing machine, understanding the characteristics of different models and assessing your own production needs is key. Below are several important factors to help you choose the most suitable pad printing equipment.

Printing Requirements and Range

First, determine the type, size, and printing area of the products you need to print. For example, if you need to print large-area patterns, you should choose a pad printing equipment with a large ink cup or an open ink tray system.

Number of Colors

Pad printing machines come in single-color, two-color, four-color, and even up to 36-color models. Single-color machines are suitable for basic logos or simple patterns, while multi-color machines are ideal for complex designs requiring precise alignment.

Custom pad printers can be tailored to professional planning. FINECAUSE has successfully manufactured and sold pad printing machines with up to 36 colors.

Fully Electric vs. Pneumatic Pad Printing Machines

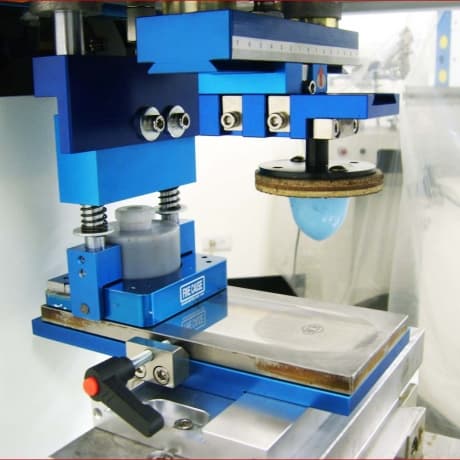

Pad printing machines can be classified into pneumatic (cylinder-driven) and fully electric models:

-

Pneumatic Pad Printer use air cylinders for movement and require an external air compressor and air tank for operation. They are suitable for applications requiring higher pressure. Pneumatic machines generally have a slightly faster printing speed but can be affected by air pressure stability. However, due to their cost-effectiveness, they remain a popular choice.

-

Fully electric pad printing machines are driven by servo motors, offering stable operation, low noise, and no need for an air compressor—just plug them in and use them. They are ideal for production environments with strict environmental requirements, providing energy savings by eliminating the need for air compressors. Although more expensive than pneumatic models, the long-term savings on electricity can be significant.

|

|

| ▲ Pneumatic Pad Printer | ▲ Fully Electric Pad Printing Machine |

Level of Automation

Depending on production scale and efficiency needs, you can choose from manual, semi-automatic, or fully automatic pad printing machines.

-

If your printing involves small batches with high variety, a semi-automatic machine is a good choice. FINECAUSE's semi-automatic pad printing machines feature a foot pedal for convenient operation, improving productivity. They also offer an automatic mode where only loading and unloading are required.

-

For high-volume printing, a fully automatic pad printing machine can save time and labor costs. Fully automated models integrate automatic feeding and unloading systems and even allow for preset output quantities, making packaging more efficient.

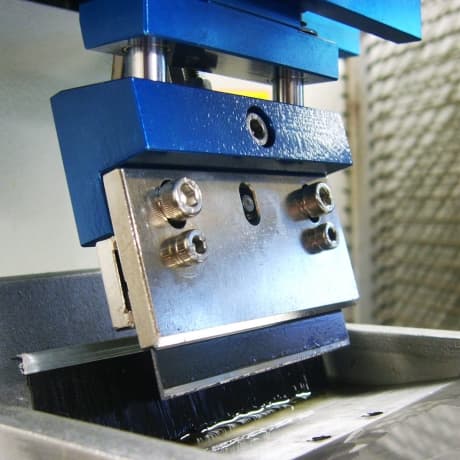

Ink Cup and Ink System

The ink cup or ink system impacts print quality and maintenance costs. Choosing a suitable sealed ink cup can reduce ink evaporation and solvent consumption, whereas an open ink tray is better for large patterns or special inks.

|

|

| ▲ Sealed Ink Cup Pad Printer | ▲ Open Ink tray Pad Printing Machine |

Precision and Stability

High-precision models ensure consistent printing quality and prevent misalignment. Digital positioning controls and high-quality rail systems enhance printing accuracy.

Ease of Operation and Maintenance

Choosing a machine with a touchscreen, PLC control system, or quick-change fixture design enhances user convenience.

-

Standard manual setting models differ from digital setting models in that digital settings significantly reduce adjustment time.

-

Smart features: Different printing materials can have separate parameter presets for quick switching, eliminating the need for reconfiguration and boosting efficiency.

Expandability and Upgradability

When purchasing a machine, consider whether it allows for future upgrades and expansions.

-

If you initially buy a semi-automatic pad printing machine, can it later be upgraded to a fully automated system?

-

Buying a new machine later could be costly, so selecting an expandable model is crucial.

FINECAUSE pad printing machines can be equipped with additional features such as slide rails, rotary tables, oval tables, suction, flipping, rotation, blowers, and automated loading/unloading systems.

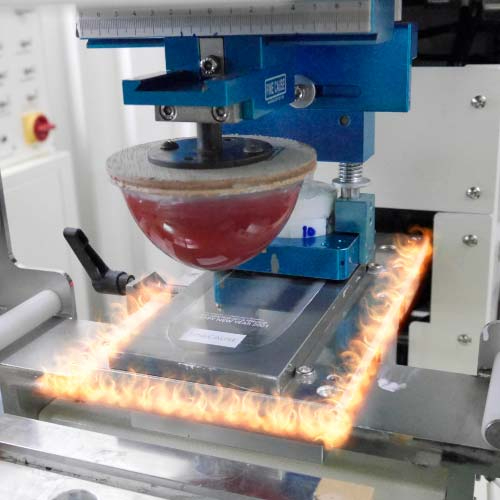

All pad printing equipment produced by FineCause can be equipped with a thermostatic pad printing system.

Patent pad printing technology: apply thermostatic pad printer to control the ink temperature to achieve a more ideal printing effect. The pad printing ink layer thickness is able to be increased. The ink deposit is complete and clean.

Price vs. Quality and After-Sales Service

While pneumatic pad printing machines are generally cheaper, they come in both high-end and low-end versions.

Many buyers focus only on price and overlook the importance of quality and after-sales service.

-

FINECAUSE pad printing machines, made in Taiwan, use high-quality components, ensuring high precision and durability, with comprehensive after-sales support.

-

Low-cost models from mainland China may seem attractive but often have issues such as poor machining accuracy, short component lifespan, and high failure rates, with unreliable after-sales service. If a machine breaks down, repair difficulties may increase long-term costs.

-

Instead of focusing solely on initial cost savings, consider long-term stability and production efficiency.

Machine Warranty Period

The warranty is crucial when purchasing a pad printing machine.

-

Most standard printing machines come with a one-year warranty, but high-quality machines typically last beyond that without major issues.

-

FINECAUSE provides a three-year warranty on standard pad printing machines and lifetime after-sales service!

Brand and After-Sales Support

Choosing a reputable brand ensures better long-term operation, reliable technical support, and spare parts availability.

-

FINECAUSE has been in business for over 20 years, with headquarters and a factory in northern Taiwan, and distributors in central and southern Taiwan, as well as overseas.

-

They offer factory visits, trial runs, and 14-day free trials on standard machines. They also provide short- and long-term rental options, with rent-to-own plans that deduct rental costs from the purchase price.

Conclusion

When selecting a pad printing machine, consider factors such as printing needs, color requirements, automation level, ink system, precision, and ease of operation. While price matters, quality and after-sales service should be top priorities. Choosing the right machine not only enhances print quality but also boosts production efficiency, making your investment more valuable.

Q&A

1. If I need to print large-area patterns but have limited space for a large machine, what should I do?

A: We recommend the FC-211GNC Medium-Sized Single-Color Semi-Automatic Pad Printing Machine, which features a 130mm ink cup for larger print areas while maintaining a compact design compared to typical large ink cup models.

2. What fully electric pad printing machines are available?

A: Options include:

-

FC-161ANE-Gen 2 – Tabletop Electric Pad Printing Machine (Cam-Driven)

-

FC-161ANS – Fully Electric Servo Single-Color Ink Cup Pad Printer

-

FC-161ENS – Electric Servo Pad Printing Machine (Sliding Steel Plate + Automatic Pad Cleaning)

-

FC-161ENS-CCD – 10.1” Image-Based Fully Electric Pad Printing Machine (Sliding Steel Plate + Automatic Pad Cleaning)

-

Custom models available upon request.

3. Will there be voltage compatibility or operational issues if used outside Taiwan?

A: The voltage can be modified. FINECAUSE machines are sold globally and come with detailed manuals, instructional videos, and real-time customer support via LINE.

4. Are there high-quality pneumatic pad printing machines available?

A: Yes! The FC-161ANC Pad Printer for Accurate Printing offers a cost-effective yet feature-rich solution with:

-

Patented adjustable doctoring system for easy ink cup pressure adjustment

-

Clean ink scraping and high printing accuracy

-

7-inch color touchscreen and PLC controller for intuitive operation

-

Multiple stored print settings for efficiency

Fully electric pad printing machines may have a higher upfront cost, but they eliminate the need for an air compressor and significantly reduce long-term electricity costs. If you require high-volume, precision printing, the FC-161ANS Fully Electric Servo Single-Color Ink Cup Pad Printing Machine is your best choice!

Regardless of which equipment you choose, we offer top-quality products and services to ensure an efficient and stable production process. Click the product names above to visit their pages for full details. Contact us anytime for more information or trial requests!

Explore our full range of standard Pad printer, custom pad printing machines, and fully automatic pad printing machines.

Links

Links