Reference

Pad Printing Machine with Temperature-Controlled Ink System

| Filename | Pad Printing Machine with Temperature-Controlled Ink System.pdf |

| File Size | 439.9KB |

| Revision Date | 2024/08/12 |

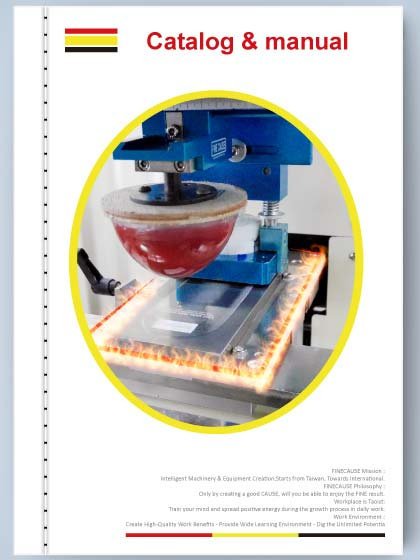

Pad Printing Machine with Temperature-Controlled Ink System

-

Have you ever faced this issue?

-

When you adjust the ink for pad printing, the initial prints look fine, but as time goes on, changes in workplace temperature or humidity cause the print quality to deteriorate. You have to readjust the ink, which lowers your efficiency and productivity!

-

-

Controlling the ink temperature can help solve these issues!

Patent Pad Printing Technology: Revolutionizing Print Quality

The temperature-controlled ink system in pad printing machines uses patented technology to achieve a more ideal printing result by regulating ink temperature. This method not only increases the thickness of the ink layer but also ensures a clean and precise ink transfer. Future high-end pad printing machines will feature ink temperature control, effectively reducing stringing and enhancing print quality.

Proven Results: The Relationship Between Ink Temperature and Print Quality

Experimental data shows that as ink temperature increases, viscosity decreases, and evaporation speed increases. When the ink temperature is raised, the ink transfer performance and ink release capability of the pad are improved, significantly reducing issues like rough edges and stringing.

Solving Common Printing Issues

Common problems in pad printing include unstable print quality, rough edges, stringing, and incomplete patterns due to ink evaporation. The temperature-controlled pad printing machine effectively addresses these issues by regulating the ink temperature, resulting in more consistent print quality.

A New Milestone in Pad Printing Technology

Regardless of whether the ambient temperature is 15°C or 30°C, the temperature control system maintains the ink at an optimal temperature, such as 40°C, throughout the production process. This reduces variables and makes the process easier to manage. A pad printing machine equipped with a temperature control system can regulate the steel plate temperature and increase ink temperature to maintain ink fluidity, ensuring complete ink transfer and stable print quality unaffected by external environmental conditions.

Increased Ink Layer Thickness

With the temperature-controlled pad printing system, you can adjust the steel plate depth to 0.035mm, resulting in a thicker ink layer with screen printing-like effects and significantly enhanced opacity. Raising the ink temperature during printing effectively reduces ink viscosity, solving the stringing issue without the need for anti-stringing agents (ST1).

Taiwan Patent

All FINECAUSE pad printing machines we produce can be equipped with temperature-controlled printing systems, transforming them into pad printing machines that control both the steel plate and ink temperature. This Taiwan patent for temperature-controlled ink cup pad printing machines (Patent No. I762245) marks a new breakthrough in pad printing technology, achieving greater precision and quality in the printing process.

Conclusion

The temperature-controlled printing system in pad printing machines not only improves print quality but also addresses many common printing issues. This technology is set to become the new standard in the pad printing industry, delivering a more stable and efficient printing experience. Whether you're looking to increase production efficiency or enhance print quality, the temperature-controlled pad printing machine is the best choice.

To download the full-color catalog in PDF format, please click the Download button.

Links

Links