Reference

Plasma Surface Treatment Machine (Rotating Gun) manual

| Filename | F1Z-1000Plasma Surface Treatment Machine_20240923.pdf |

| File Size | 666.2KB |

| Revision Date | 2024/09/23 |

F1Z-1000-Plasma Surface Treatment Machine (Rotating Gun)

Introduction to Plasma 3D Surface Treatment Technology:

The energy of particles in low-temperature plasma is generally about several to more than ten Electronvolt, which is greater than the bonding energy of polymer materials (several to more than ten Electronvolt), which can completely break the Chemical bond of organic macromolecules to form new bonds; but far lower than high-energy radioactive rays, it only involves the surface of the material and does not affect the performance of the matrix. In the low-temperature plasma in the state of non-Thermodynamic equilibrium, electrons have high energy, can break the Chemical bond of molecules on the surface of materials, improve the chemical reaction activity of particles (greater than that of thermal plasma), and the temperature of neutral particles is close to room temperature.

These advantages provide suitable conditions for the surface modification of thermosensitive polymer. Through low-temperature plasma surface treatment, the material surface undergoes various physical and chemical changes, or undergoes etching and roughness, or forms a dense cross-linked layer, or introduces oxygen-containing polar groups, resulting in improved hydrophilicity, adhesion, dyeability, biocompatibility, and electrical properties.

The surface of the material is treated under the appropriate process conditions, so that the surface Morphogenesis of the material has changed significantly. A variety of oxygen containing groups have been introduced, which makes the surface change from non-polar, hard sticky to polar, easy sticky and hydrophilic, which is conducive to bonding, coating and printing.

Plasma has the following major effects on material surface treatment:

-

Activation: Significantly improves the wetting performance of the surface, forming an active surface;

-

Cleaning: Remove dust and oil stains, finely clean and remove static electricity;

-

Coating: Provide a functional surface through surface coating treatment; Improve the adhesion ability of the surface, improve the reliability and durability of surface bonding.

After using atmospheric pressure plasma technology for treatment, surface energy can be improved for various materials such as polymer plastics, ceramics, glass, PVC, paper, or metals. Through this treatment process, the improvement and enhancement of surface tension characteristics of product materials can be more suitable for industrial coating, bonding and other treatment requirements.

For example, in electronic products, the coating treatment of LCD screens, the surface spray screen printing of structural components such as casings and buttons, the cleaning of PCB surfaces by removing glue and dirt, the treatment before adhesive bonding of lenses, the treatment before wire and cable coding, etc. Treatment before pasting the lampshade, brake pad, and door sealing strip of automotive industrial vehicles; fine harmless cleaning treatment for metal components in the mechanical industry, treatment before mirror coating, and treatment before sealing between various industrial materials, etc. The treatment before gluing the edge sealing position in printing, packaging, and box pasting machinery, etc. In the medical device industry, the treatment before adhesive bonding between needles and plastic catheters, etc.

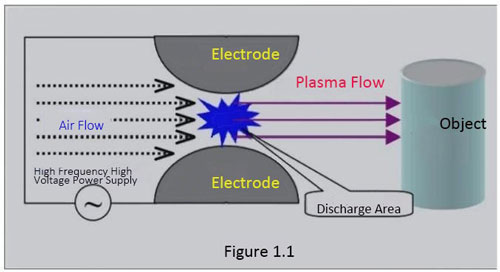

The best solution for modifying the surface of three-dimensional objects is to use low-temperature plasma flow treatment technology. The principle is shown in Figure 1.1. Apply AC high-frequency high voltage to both ends of the electrode, causing the air between the two electrodes to generate a gas arc discharge and form a plasma zone. Plasma arrives under the blowing of airflow the purpose of modifying the 3D surface by processing the surface of the object.

External structure and description of the host:

Equipment structure (Front side)

1. Alarm:

If the air pressure does not reach 0.05Mpa, the air pressure is over 0.3MPa, the working current is too high, and the temperature is too high, an alarm sound will be emitted.

2. Power:

This is the main switch of the equipment; when the switch is in a raised and no light state, the host is in a power off state, and when the switch is in a light state, the host is in a power on state. Lock the air pressure regulating valve.

3. Start:

After the device power switch is turned on, the nozzle will be in standby mode for spraying plasma. Press the start button to start the spraying work.

4. Barometer:

After the power switch is turned on, the gas display screen displays the current working air pressure value.

5. Pneumatic control:

Adjust the knob clockwise to increase the air pressure and counterclockwise to decrease it (it is more commonly used to adjust the working air pressure to between 40KPA and 60KPA).

6. Display screen:

Display device, displaying the operating status of the device, providing power supply voltage, current, real-time power, and cumulative energy usage. (About 10W in standby mode.)

7. Power control:

Users can adjust the power through the potentiometer knob to get the appropriate power. (Slight adjustment, do not use excessive force to avoid damaging the potentiometer.)

.....more...

.......please download the file if you need the manual content, please click the Download button to download.

Links

Links