Reference

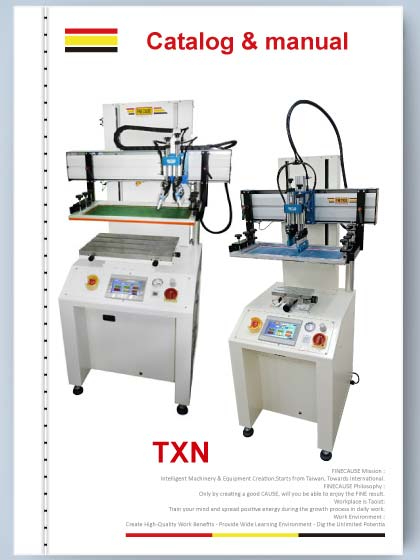

Screen Printing Machine by Dual-Axis Servo-FA-300/500TXN

| Filename | screen_printer-TXN-en.pdf |

| File Size | 505.3KB |

| Revision Date | 2024/08/27 |

Why Choose a Dual-Axis Servo Screen Printing Machine?

Higher Print Quality

The high-precision control capability of the dual-axis servo system ensures the stability and consistency of print quality. Whether it's fine lines or other details, this system delivers exceptional results throughout the printing process

Increased Production Efficiency

One of the significant advantages of the dual-axis servo screen printing machine is its high-speed printing capability. This greatly enhances production efficiency and reduces printing costs, making it particularly attractive for companies engaged in large-scale production.

Greater Reliability

The stability and reliability of the dual-axis servo system ensure that the printing machine operates for extended periods without failures or deviations, reducing downtime and further improving production stability.

Advantages of Dual-Axis Servo Screen Printing Machines

High-Precision Printing

The dual-axis servo system provides extremely high positioning accuracy and motion control capabilities, ensuring precise control of the machine's actions during the printing process to achieve high-precision printing. This level of precision not only enhances production efficiency but is also particularly beneficial for large-scale printing applications, saving time and costs.

Stability and Reliability

The dual-axis servo system offers excellent stability and reliability, maintaining high-precision motion control over long periods of operation. This reduces the risk of deviations or malfunctions during the printing process, ensuring consistent print quality.

Screen Printing Machine by Dual-Axis Servo-FA-300/500TXN

-

The larger left and right printing speed value, the faster; the fastest can reach 999mm/1 second.

-

Magnetic squeegee clip (patent no. M390871)-The squeegee position can be easily slide, making adjustments or disassembly effortless.

-

The screen printing machine utilizes a pneumatic squeegee seat assembly for linear elevation.

-

The squeegee downward pressure is controlled by stepper motor, enabling fine adjustment of the downward distance. This setup is specifically designed for advanced screen printing applications.

-

Linear lifting can prevent squeegee height from deviation.

-

Linear lifting can prevent ink from flowing out of the screen stencil.

-

Make the screen stencil cleaning more convenient and fast.

-

Printing and screen stencil lifting (dual-axis)- The screen stencil lifting adopts servo motor, allowing precise adjustment of the snap-off distance, making the production process more systematic.

-

Printing adopt servo motor and linear guideway with ball screw rod.

-

Screen stencil lifting adopt servo motor with shaft bushing.

-

The servo linear lifting can be set to reduce the speed of lowering or raising the screen stencil at specific positions.

-

The screen printing machine adopts 7" HMI (TFT touch interface) and built in 5 languages, Traditional Chinese, English, Indonesian, Vietnamese, and Thai.

-

With I/O (input/output), each sensor location is shown in whole area of the machine. The screen stencil usage times can be set. When the set value reaches, the machine will automatically stop and alarm.

FA-300TXN-Screen Printing Machine by Dual-Axis Servo Specifications/Video, click here...

FA-500TXN-Flat Surface Screen Printer (Dual-Axis Servo Motor) Specifications/Video, click here...

...For the complete color image catalog DM, please download the file by clicking the Download button.

Links

Links