Products

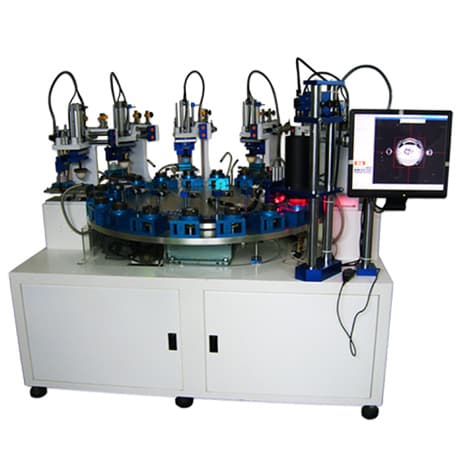

Multicolor pad printer/Fully automatic multi color pad printing machine

Multicolor pad printer/Fully automatic multi color pad printing machine

Product Info

-

A. Free selection of 1 to 36 colors

-

B. Pre-treatment options such as corona, plasma, and static dust removal can be set before printing

-

C. Automatic 360-degree flip printing

-

D. Automatic latitude and longitude rotation for a total of 720 degrees

-

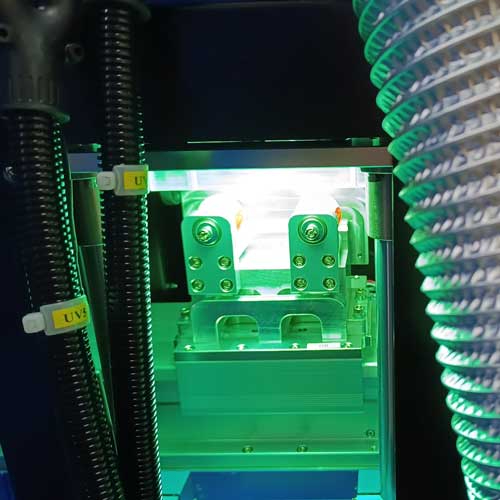

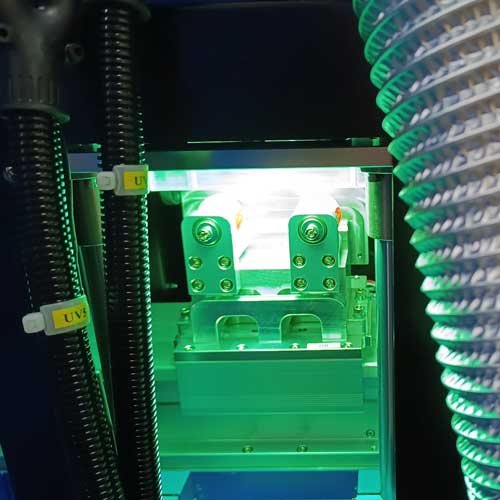

E. Optional UV exposure after printing

-

F. Automatic material sorting and discharge

-

G. Multi-station, precise positioning, innovative design, flexible application

-

H. Custom printing machines can be planned and designed for a variety of items.

The most advanced, innovative, and precise pad printing machines are at FINECAUSE ! A full range of models available, welcome to visit.

▇ Automatic Pad Printing Machine Features:

-

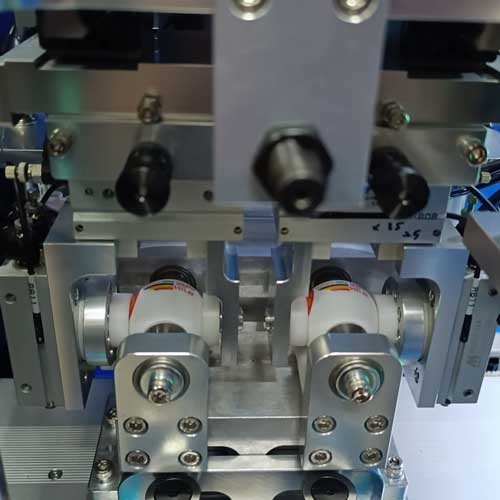

With a pressure-regulating ink scraping system (Patent No. M311585), the ink cup scraping pressure can be adjusted easily.

-

The 3 stage cylinder for loading and unloading arm allows for quick and efficient object handling, effectively enhancing the productivity of the equipment.

-

The object movement utilizes linear conveyor, providing agile movement and precise positioning, with the repeatability ±0.01mm.

-

Pad printing machine positioning accuracy: ±0.02mm.

-

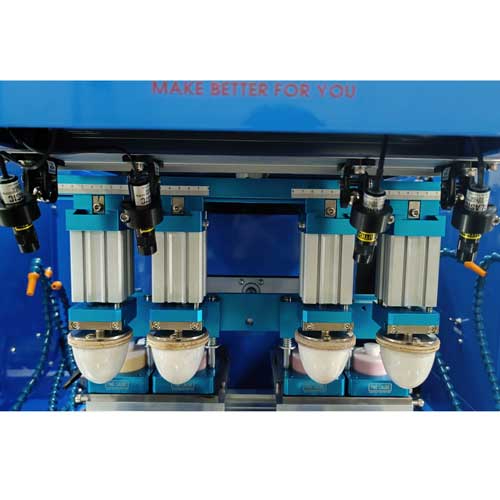

With 9 sets of 4-color pad printers, each pad printing machine includes 4 ink cup sets and 2 cliche. (The printing pad can be activated individually) for 1~36 color printing options.

-

Each pad printer capable of executing 4 colors, with a total of 9 pad printing machines, allowing for a total of 36 colors to be printed.

-

-

Each set of pad printing machines is equipped with an cross red light laser pointer, making it easier for operators to align for multi-color printing.

-

32 sets of customized rotary jig for for table tennis.

-

9 sets of movable servo rotary motors. (This is optional function.)

-

Rotary angles from 0 to 360 degrees can be set freely by touch screen. This feature is equipped on 5 sets of 4-color pad printers and 4 sets of UV devices; the servo rotary motors at the printing stations can be freely locked to any station of these 5 pad printing machines for different position printing. <The fixed hole positions (threads/sleeves) are increased to reduce the risk of tooth fracture.>

-

- 3 stage cylinder for loading and unloading arm (picking up 2 pcs at a time).

-

The latitude and longitude turning mechanism is driven by a servo motor, enabling 360-degree arbitrary angle setting. And the latitude and longitude axes are interchanged using cylinder clamps.

-

Each 4-color pad printer is equipped with 4 pcs of air drying device (36 pcs in total).

-

UV lamp modules (height adjustable) is a total of 6 sets, with digitally adjustable UV power.

-

Optimized design for the discharge conveyor belt and ball collection tray.

-

Dual-side discharge allows for separate quantity settings for each side, making it easy to set the discharge amount for each side, facilitating packaging.

-

-

-

An emergency stop and pause button are installed at the end of the conveyor belt.

-

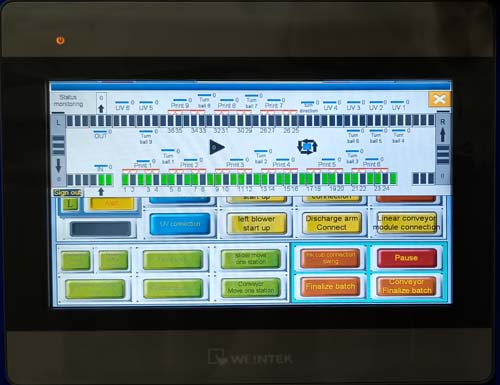

With ball position movement status display, printing or processing only occurs when a ball is detected in position.

-

-

Equipped with safety light curtains and safety doors; operation will immediately stop if a person enters the light curtain detection area or opens the safety door.

-

With 2 sets of 10.0" 16.7M TFT color touch screens and 7 sets of 7.0" 16.7M TFT color touch screens.

-

I/O (input/output) and each sensor locations are shown in the touch screen.

-

With abnormal alarm display, it is convenient for production line personnel to eliminate abnormalities quickly.

-

Abnormality log and operation log for quick reference by production line personnel to review past issues and operation records.

-

The printing pad usage count and cliché usage count can be set. When the set value is reached, the device will stop and notice automatically.

-

Built-in 3 languages: Traditional Chinese, English, and Vietnamese.

-

- Utilizing programmable logic controller (PLC) for easy addition or modification of functions.

-

Production history function: built-in smart bar chart that the productivity, operation time, production speed, etc in the past 30 days can be shown.

-

With smart factory Industrial Internet of Things (I.O.T.), wherever you are, you can view the productivity report by downloading the FineCause APP.

-

Automatic printing systems can be customized for various types of balls such as table tennis, lottery balls, etc.

-

Estimated productivity:

1800~2200 pcs/hr (printing 1~18 colors).

500~600 pcs/hr (printing 1~36 colors).

Specifications

| Model | FC-1636-BRC |

|---|---|

| Printing Color | 36 |

| Suitable Cliché Size | L:200 W:170 H:10 mm |

| Estimated Productivity | 1800~2200 pcs/hr (printing 1~18 colors) 500~600 pcs/hr (printing 1~36 colors) |

| Machine Size | L: 625 W: 202 H:170 cm |

| Optional Device | Cross red light laser pointer Air drying device UV curing device Customized rotary jig Discharge conveyor belt |

| Net Weight | 6300 kg |

Videos

-

Automatic Pad Printing Machine with Multiple Stations/multi-color PadPrinter-36-Color-FC-1636-BRC-FGM

Automatic Pad Printing Machine with Multiple Stations/multi-color PadPrinter-36-Color-FC-1636-BRC-FGM

-

FC-606BRC Six-color Ink Cup Round Plate Pad Printer

FC-606BRC Six-color Ink Cup Round Plate Pad Printer

-

FC-166BRC- Six color Ink Cup Round Plate Pad Printer (formerly FC-606OP)

FC-166BRC- Six color Ink Cup Round Plate Pad Printer (formerly FC-606OP)

-

FC-606 OP Central Mint Commemorative Coin Six-color Pad Printer

FC-606 OP Central Mint Commemorative Coin Six-color Pad Printer

-

Pad printing machine/Pad printer Production Data APP

Pad printing machine/Pad printer Production Data APP

-

Fine Cause Prints Your Life

Fine Cause Prints Your Life

Downloads

-

FC-606 OP 6-Color Round-Plate/Ink-Cup Pad Printer

FC-606 OP 6-Color Round-Plate/Ink-Cup Pad Printer

FC-606 OP 6-Color Round-Plate/Ink-Cup Pad Printer

-

2016 Feature of FINECAUSE Screen Printer

2016 Feature of FINECAUSE Screen Printer

2016 Feature of FINECAUSE Screen Printer

-

CITD project research and development of Industry Bureau, Ministry of Economic Affairs

CITD project research and development of Industry Bureau, Ministry of Economic Affairs

CITD project research and development of Industry Bureau, Ministry of Economic Affairs

-

Pad printing technology

Pad printing technology

Pad printing technology

-

Pad printer machine scraping ink is not clean, problem resolve

Pad printer machine scraping ink is not clean, problem resolve

Pad printer machine scraping ink is not clean, problem resolve

-

How to Select Pad-Print and Screen-Print

How to Select Pad-Print and Screen-Print

How to Select Pad-Print and Screen-Print

RFQ form

Thank you for your query, Our specialist will contact you soon.

Links

Links